- No products in the cart.

Volvo SD70F Single Drum Compactors Service and Repair Manual PDF

Size: 42.07 MB

Language: English

Make: Volvo

Machine: Single Drum Compactors

Document: Service and Repair Manual, Hydraulic and Electrical Diagrams

Model: Volvo SD70F

US $50

Brands:

Volvo

Description

Volvo SD70F Single Drum Compactors Service and Repair Manual PDF

Size: 42.07 MB

Language: English

Make: Volvo

Machine: Single Drum Compactors

Document: Service and Repair Manual, Hydraulic and Electrical Diagrams

Model: Volvo SD70F

Page: 4194 Pages

Detail Contents:

SD70F

Descriptions

- Air cleaner, description

Alternator, description

Control unit, description

Conversion tables

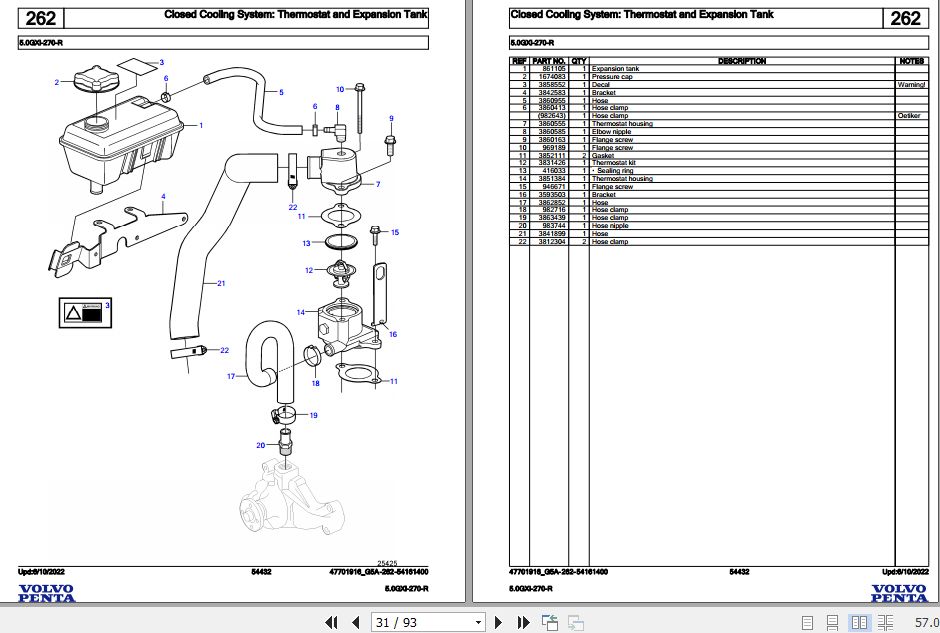

Cooling system, description

Description, complete machine

Drum drive motor, description

Drum eccentric, description

Drum, description

Electric welding

Electrical troubleshooting

Engine difficult to start

Engine does not start

Engine overheated

Engine, description

Environmentally safe handling

Frame, description

Fuel tank, description

Heavy exhaust smoke development

Hydraulic brake system, description

Hydraulic oil cooler, description

Hydraulic oil tank, description

Hydrostatic pump, description

Instruments and controls, overview

Low engine oil pressure

Low voltage

Machine identification

Paint and Finish

Precaution when working on the electrical system

Rear axle drive motor, description

Rear axle, description

Safety when lifting and supporting complete machine

Safety when working on hydraulic system

Safety when working on the electrical system

Service position

Starter motor, description

Starting with booster batteries

Steering system, description

Steering, specifications 1

Steering, specifications

Towing procedures

Transporting the machine

Troubleshooting, general

Vibration motor, description

Inspection

Service Bulletins

- Battery box steps retainer bolts

Battery change

Biodiesel fuel for Volvo CE

Check method on engine oil consumption

Fuel sampling, method

Hydraulic oil dye

Initial eccentric oil change interval

Lubricant specifications and service interval changes

New fastener assortment

Portable refillable O-ring kits

Preservation

Reports

SD70 77 77DA, Swivel joint kit

Software Distribution Procedure

Volvo Product incident accident report & Interview Form

Repair

- Air cleaner, installing

Air cleaner, primary filter replacing

Air cleaner, removing

Air cleaner, secondary filter replacing

Alternator, installing

Alternator, removing

Arrival Inspection, according to Inspection Programme

Axle hubs, changing oil

Axle hubs, checking oil level

Axle, installing

Axle, removing

Axles, checking oil level

Batteries, replacing

Battery maintenance

Breather, replacing

Carrier bearings, replacing

Cleaning engine compartment

Cleaning of the machine

Coolant mixture

Coolant, changing

Cooling fan, replacing

Cooling package, installing 1

Cooling package, installing

Cooling package, removing 1

Cooling package, removing

Delivery Inspection, according to Inspection Programme

Drive motor, installing

Drive motor, removing

Drum carrier, changing oil

Drum carrier, checking oil level

Drum drive planetary oil level, checking

Drum drive planetary oil, changing

Drum eccentric, changing oil

Drum eccentric, checking oil level

Drum shock mount, replacing 1

Drum shock mount, replacing

Drum, checking

Drum, installing

Drum, removing

Eccentric shaft coupling, replacing

Eccentric weight bearings, replacing

Eccentric weight, installing

Eccentric weight, overhauling

Eccentric weight, removing

Engine hood, installing

Engine hood, removing

Engine mounts, replacing

Engine oil and filter, changing

Engine, air cleaner maintenance

Engine, installing

Engine, removing

Fan belt and or alternator belt, replacing

Fan belt, check

Fuel filters, replacing

Fuel level sender, replacing

Fuel line, water separator, check and drain

Fuel, coolant and oil leaks, checking

Hydraulic motor, replacing

Hydraulic oil filter, replacing

Hydraulic oil suction strainer, cleaning

Hydraulic oil tank, installing

Hydraulic oil tank, removing

Hydraulic oil, changing

Hydraulic system, checking oil level

Hydrostatic controller, installing

Hydrostatic controller, removing

Hydrostatic pump, installing

Hydrostatic pump, removing

Location of components

Machine view

Maintenance of Stored Machines, according to Inspection Programme

Maintenance service, daily

Maintenance service, every 50 hours

Maintenance service, every 250 hours

Maintenance service, every 500 hours

Maintenance service, every 1000 hours

Maintenance service, every 2000 hours

Maintenance service, every 3000 hours

Maintenance service, first 50 hours

Maintenance service, general

MS.Internal.Documents

Multi function brake valve solenoid and cartridge, replacing

Oil and filtration 1

Oil and filtration

Operation numbers for additional work

Operator’s protective structure, component locations

Operator’s protective structure, tilt position

Operator’s seat, installing

Operator’s seat, removing

Padfoot drum scrapers, replacing

Parking brake performance

Parking brake pressure switch, replacing

Periodic maintenance

Propulsion control lever, replacing

Pump coupling, installing

Pump coupling, removing

Radiator and coolers, cleaning

Rear axle oil, changing

Reverse alarm, replacing

Seat safety belt, replacing

Silencer, replacing

Smooth drum scrapers, replacing

Starter motor, installing

Starter motor, removing

Starter switch (engine start switch), replacing

Steering control unit, installing

Steering control unit, removing

Steering cylinder, replacing

Steering pressure, checking and adjusting

Torque hub, installing

Torque hub, removing

Tyres, wear and air pressure, checking

Vibration motor, installing

Vibration motor, removing

Vibration pump, installing

Vibration pump, removing

Wheel nuts, check torque

Wheel, removing and fitting one 1

Wheel, removing and fitting one 2

Wheel, removing and fitting one

Diagrams

- Component list, Diodes

Component list, fuses

Component list, relays

Component list, sensors

Electrical components

Hydraulic diagram, schematic 2

Hydraulic diagram, schematic index

Wiring diagram 1

Wiring diagram 1

Wiring diagram 2

Wiring diagram 3

Wiring diagram 4

Wiring diagram 5

Wiring diagram 6

Wiring diagram 7

Wiring diagram index

Specifications

- Alternative fuels

Battery, specifications

Brake, specifications

Critical mounting torques

Drum, specifications

Electrical system, specifications 1

Electrical system, specifications

Engine, specifications

Environmental requirements

Fuel, lubricant and filling capacities

Hydraulic connections, tightening torques

Lubrication and oil system, general specifications

Machine dimensions

Machine weight, specifications

Power transmission, specifications

Specifications, general

Tightening torque, specifications

Wheels, specifications

Time Guide Currrent generation

Service Programme, SD70_SD77

Special tool Manual

- General

Index

Hooks

1. Enviroment and Safety equipment

2. Measuring equipment

3. Tightening and Loosening tools

4. Lifting equipment

5. Pullers and Pressing equipment

6. Drifts

7. Guide pins and Guide sleeves

8. Pliers

9. Fixtures

10. Tech Tool

11. Spare parts

21 Time Guide Old generation

11 Time Guide Previous generation

40 RM Compaction Time guide old version

- Drum

Hydraulic

Electrical

Engine

Structural

Drive system

Water

41 RM Compaction ABG Time Guide Old

- Foreword

Drum

Hydraulic

Electrical

Engine

Structural

Drive system

Water

42 RM Paving Systems ABG Time Guide Old

- Foreword

Screeds

Hydraulics

Structural

Engine

Drive system

Electrical

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution