- No products in the cart.

Volvo L25B Wheel Loader Service and Repair Manual PDF

Size: 60.50 MB

Language: English

Make: Volvo

Machine: Wheel Loader

Document: Service and Repair Manual, Hydraulic and Electrical Diagrams

Model: Volvo L25B

US $50

Brands:

Volvo

Description

Volvo L25B Wheel Loader Service and Repair Manual PDF

Size: 60.50 MB

Language: English

Make: Volvo

Machine: Wheel Loader

Document: Service and Repair Manual, Hydraulic and Electrical Diagrams

Model: Volvo L25B

Page: 4132 Pages

Detail Contents:

1 L25 B SPECS

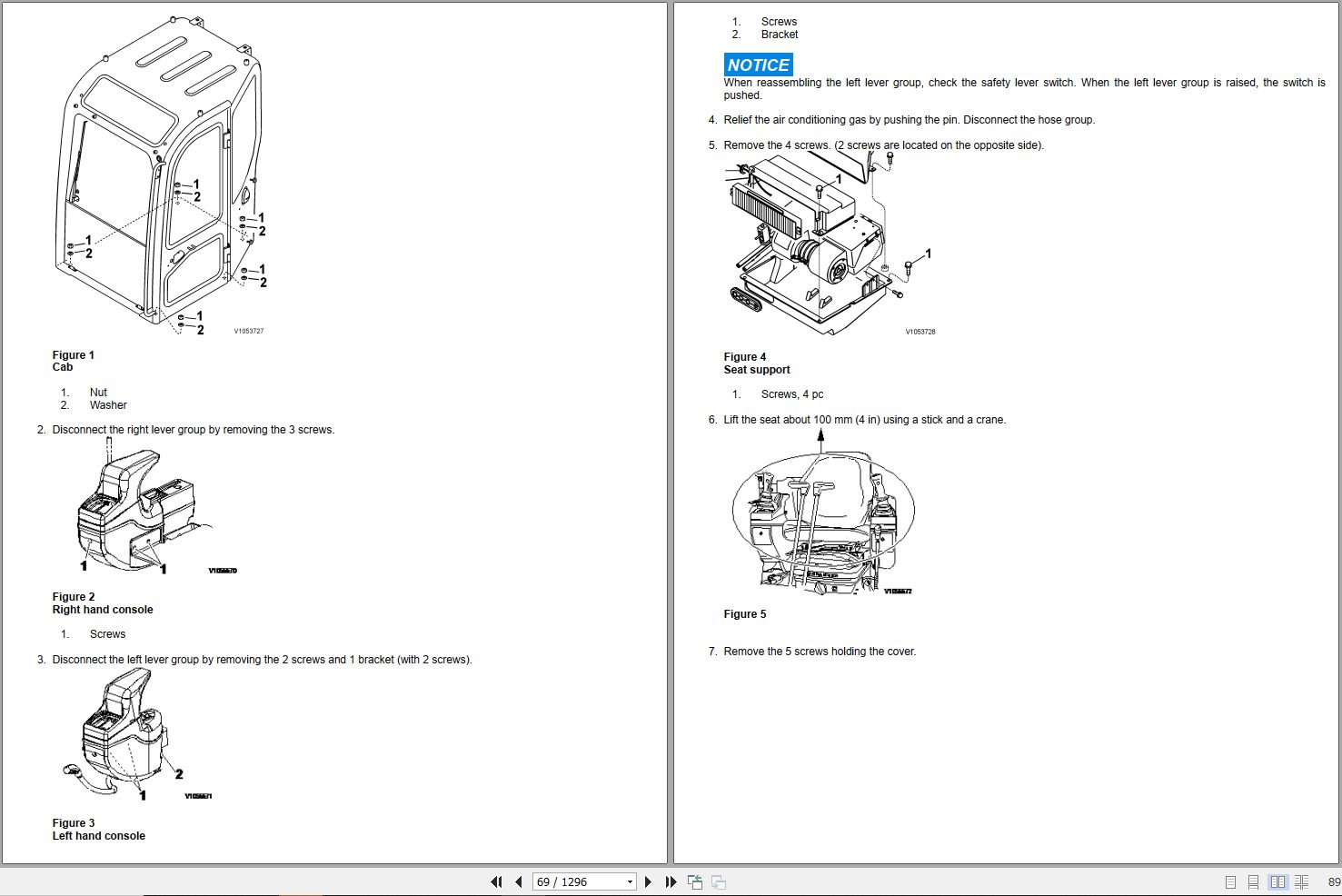

AC Disassembly and assembly

Action to be taken in case of abnormal lubricating oil consumption

Air cleaner primary filter, change

Air cleaner secondary filter, change

Alternator, installing

Alternator, removing

Axle, installing

Axle, removing

Axles, changing oil

Battery and alternator test procedure

Battery, cables and connections, check

Battery, description

Belt, changing

Belts and belt tension, check, replace when needed.

Bolted joints, check tightening torque

Boom Suspension System, description

Brake cylinder, replacing

Brake design

Brake fluid level, check

Brake pads, replacing

Brake system, bleeding

Bss

Cab filter, replace (clean when necessary)

Cab mounts, tightening torques

Cable markings

Camshaft, description

Care Track

CareTrack Telematics system

Charging batteries

Cleanliness when working on hydraulic components

Cleanliness, braking and hydraulic system

Combination sensor, check

Compression test

Connectors, overview.

Dark-coloured fuel

Decal electronic unit

Description brake system

Description

Diesel heater, description

Diesel heater, principles

ECU 2, functions

EGR (exhaust gas recirculation) sensor, replacing

Electric welding

Electrical components, engine side, description

Electrical schematic

Electrical system, description

Engine radiator and hydraulic oil cooler, check (clean when necessary)

Engine, description

Engine, installing

Engine, oil and filter, change.

Engine, oil level, check

Engine, removing

Error code, troubleshooting

E-tool Cab support

E-tool Guide bolts

E-tool Sleeve

Exhaust manifold, replacing gasket

External leakage at quick attachment bracket

Fan belt and or alternator belt, replacing

Fault mode diagnosis

Frame joint, assembly of separated machine

Frame joint, changing bearing, machine separated (on load unit frame)

Frame joint, Replacing the front pivot bearing with machine separated

Frame joint, replacing the rear pivot bearing with machine separated

Frame joint, separating machine

Fuel filters, primary and secondary filter, replace

Fuel filters, replacing

Fuel pump, installing

Fuel pump, removing

Fuel sampling, method

Fuel system, description

Fuel tank, conversion kit

Gap between attachment and attachment bracket causing leakages

General information to note when working on the hydraulic system

Hand INCH VALVE

Hydraulic diagram transmission

Hydraulic diagram working hydraulics

Hydraulic diagram, Boom Suspension System

Hydraulic diagram, control valve

Hydraulic diagram, steering 1

Hydraulic diagram, steering

Hydraulic motor, replacing

Hydraulic oil filter, changing

Hydraulic oil level, check

Hydraulic oil tank, description

Hydraulic pressure, check

Hydraulic pump 45L-MIN

Hydraulic pump, replacing

Hydraulic pumps, description

Hydraulic system, changing oil.

Hydraulic system, repair of hydraulic components in workshop

Hydrostatic pump charge pressure, check and adjust

Hydrostatic pump cut off valve, check and adjust

Hydrostatic pump mechanical zero position, check and adjust

Hydrostatic pump, description

Idling speed, checking and adjusting

Implement attachment, repacking removed hydraulic cylinder

Inching and brake pedal, adjusting

Induction sensor for output shaft, changing

Injection valve, check

Injector nozzle, carbon built up

Instrument panel, description

Instrument panel, electrical circuit

Introduction of new engines with Tier 3 exhaust emission level

Introduction of new stronger T-fitting

Leakage by the cover of the hydraulic suction filter

Lift cylinder, replacing

Lock cylinder

Low and high idle, checking

Lubrication system, description

Lubrication

Machine, transporting

Main control valve, description

Maintenance service, daily

Maintenance service, every 100 hours

Maintenance service, every 500 hours

Maintenance service, every 1000 hours

Maintenance service, every 1500 hours]

Maintenance service, every 2000 hours

Maintenance service, every 4000 hours

Maintenance service, every 6000 hours

Maintenance service, general

New assembly method for quick coupler pins

New cab door hinge repair kit

New cab window hinge repair kit

New electrical card with anti theft option

New fuel feed pump with integrated hand pump

New fuel level sensor

New relay for hydraulic oil cooler fan

New routing of return oil hose between drive pump and hydraulic oil tank

New sun gear shaft

New TechTool VCADS Pro interface

New tilt cylinder

Oil pump, description

Overview lighting, devices

Planetary gear failures on front and rear axles

Power transmission, description

Pressure settings steering system

Primary pressure limiting valve, checking and adjusting

Radiator, installing

Radiator, removing

Rear window, replacing

Recomended tools

Recommended lubricants

Relays and fuses in electrical distribution box

Relays and fuses in engine compartment

Relocation of pressure relieve valve for auxiliary pump

Repairs of minor damage on internal and external plastic parts (scratches, dents, breaks)

Replacing instruction for the EGR (exhaust gas recirculation) sensor

Reporting of product misuse & near-miss report

Reports

Secondary pressure limiting valve, checking and adjusting

Service brake, brake pads, check

Service positions

Special tool catalog

General

Index

Hooks

1. Enviroment and Safety equipment

2. Measuring equipment

3. Tightening and Loosening tools

4. Lifting equipment

5. Pullers and Pressing equipment

6. Drifts

7. Guide pins and Guide sleeves

8. Pliers

9. Fixtures

10. Tech Tool

11. Spare parts

Start hydraulic pump control, check and adjust

Starter motor, replacing

Steering cylinders, locking of pivot pins, check

Steering system, checking and adjusting working pressure

Steering system, description

Steering valve, installation

Steering valve, removal

Symptom and malfunction

Test-run and check

The machine, check for external damages, cracks and wear damages

Thermostat, replacing

Tightening torque on electrical card

Tightening torques

Tilt cylinder, replacing

Tilting and lifting cylinders 2

Tilting and lifting cylinders

Time Guide Currrent generation

Time Guide Old generation

Time Guide Previous generation

Towing a disabled machine

Travel motor, description 1

Travel motor, description

Troubleshooting and actions to fix problems brakes

Troubleshooting and actions to fix problems steering

Troubleshooting chart Transmission

Tyres, wear and air pressure, checking

Vacuum pump, connection

Valves, adjusting

Volvo Product incidentaccident report & Interview Form

Warranty inspection 100 hours

Warranty inspection 1000 hours

Warranty inspection

Water separator, drain

Wheel nuts, check torque

Windscreen, replacing

Wiring diagram 1

Wiring diagram 2

Wiring diagram 3

Wiring diagram 4

Wiring diagram 5

Wiring diagram 6

Wiring diagram 7

Wiring diagram 8

Wiring diagram 9

Wiring diagram 10

Wiring diagram 11

Wiring diagram 12

Wiring diagram 13

Wiring diagram 14

Wiring diagram 15

Wiring diagram 16

Wiring diagram 17

Wiring diagram 18

Wiring diagram 19

Wiring diagram, figure text

Work on the machine’s electrical system

Working hydraulic system, component location

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution