- No products in the cart.

Volvo L110E Wheel Loader Service and Repair Manual PDF

Size: 96.42 MB

Language: English

Make: Volvo

Machine: Wheel Loader

Document: Service and Repair Manual, Electrical and Hydraulic Diagram

Model: Volvo L110E

US $50

Brands:

Volvo

Description

Volvo L110E Wheel Loader Service and Repair Manual PDF

Size: 96.42 MB

Language: English

Make: Volvo

Machine: Wheel Loader

Document: Service and Repair Manual, Electrical and Hydraulic Diagram

Model: Volvo L110E

Page: 4774 Pages

Detail Contents:

1-L110E

Descriptions

- Abbreviations, wiring diagrams

Accelerator Pedal

Air cleaner, description

Air filter pressure

Alternator, description

APS II

APS

Attachment locking

Automatic engine shut-off

Automatic lift arm lowering (Return to dig)

Axle oil temperature

Back-up alarm

Barometric pressure

Battery, description

Boom Suspension System (BSS)

Boost pressure

Brake pressure charging

Brake pressure

Brake test

Cable and component designations

Cable and component marking explanations

Camshaft speed

Camshaft, description

Central lubrication, status indication

Central lubrication

Charge-air temperature

Charging batteries

Cleanliness, brake and hydraulic systems

Comfort Drive Control, description

Communication cable explanation

Component list 1 Alternator, batteries, capacitors, electronic units

Component list 2 Diodes

Component list 3 Fuses

Component list 4 Heating coils, instruments, service connections

Component list 5 Lights

Component list 6 Control lights warning lights

Component list 7 Solenoid valves

Component list 9 Relays

Component list 10 Signals, shift solenoids

Component list 11 Sensors

Component list 12 Switches

Component list Motors, resistors, monitoring system

Connecting rod, description

Connectors, overview

Connectors, position

Control unit, description 1

Control unit, description

Control valve, description FIG1

Control valve, description

Coolant Level

Coolant temperature, engine

Coolant temperature, outlet radiator

Cooling fan adjustment

Cooling system, description

Cooling system, description1

Crankshaft, description

Cylinder head gasket, description

Cylinder head, description

Cylinder liner, description

D7 cylinder block with crankcase ventilation, description and operation

Description of table for software functions

Description torque converter

Description

Differential lock

Display panel and keypad, general

Display panel, information displays

Display panel, initial display

Display panel, operating display

Downshifting signal

Electric welding

Electrical distribution box, description

Electrical symbols and designations

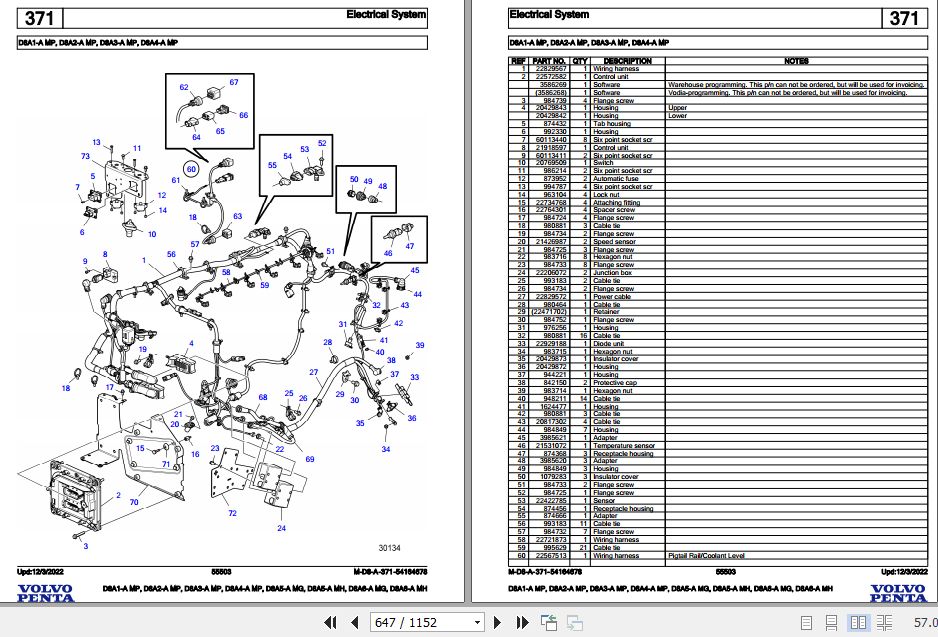

Electrical system, description

Electrical system, work instructions

Electronic control system, description

Engine control unit E-ECU, description

Engine mounting, description

Engine Oil Level

Engine oil pressure

Engine Protection

Engine Shutdown

Engine speed for E-ECU

Engine speed for V-ECU

Engine timing gear, description

Engine, description 1

Engine, description 2

Engine, description

Exhaust Gas Recirculation (EGR)

Fan speed control, description

Foot brake valve, description

Frame ground connections and signal ground

Frame, description

Fuel consumption

Fuel feed pump, description

Fuel filter, description

Fuel Level

Fuel rail, description

Fuel system, description

Fuel temperature

Fully automatic

Gear Selector

Gearshifting solenoids

General description

Hand Throttle

High pressure fuel pump, description

Hydraulic Oil Level

Hydraulic oil temperature

Hydraulic power limitation

Hydraulic pump, description FIG1

Hydraulic pump, description

Hydraulic system, description FIG1

Hydraulic system, description

Increased engine rpm

Increased fan speed for AC

Indication of serious engine fault

Information display unit, general

Information display unit, setting

Injectors, description

Injectors

Instructions for working with electronic fuel injection

Instrument control unit I-ECU, description

Instruments

Internal Exhaust Gas Recirculation (IEGR), description

Interruption in computer communication

Interval Wiper

Key feed

Lighting, description

Lubrication system, description

Mechanical release of parking brake

Middle instrument panel with warning lights

Oil pump, description

Outdoor temperature

Output brake pressure

Overspeed, transmission

Parking brake, description

Parking brake

Pistons, description

Preheating coil, description

Preheating of inlet air

Protection for high fuel temperature, common rail

Recommended lubricants, oils

Reduced computer communication

Repairing hydraulic system

Reversible cooling fan, electric description

Reversible cooling fan, hydraulic diagram description

Reversible cooling fan, trouble-shooting fault indication.

Reversible cooling fan

Secondary steering, description

Secondary steering

Service display unit, axles and brakes

Service display unit, electrical control input signals 1

Service display unit, electrical control input signals 2

Service display unit, electrical control input signals 3

Service display unit, electrical control output signals 1

Service display unit, electrical control output signals 2

Service display unit, electrical system battery voltage

Service display unit, engine

Service display unit, general

Service display unit, hydraulics

Service display unit, settings

Service display unit, transmission

Service interval

Service panel, electrical feed sensor

Setting software parameters

Shift valve, description

Shift valve, function description

Soft start and safety for AC

Software functions per function group

Software, description

Speed limitation for lever steering (CDC)

Speed limitation

Starter motor engagement

Starting system, description

Steering cylinder, sectional view

Steering valve, description

Steering, description

Steering, function description

System voltage

Temperature induction air

Theft protection

Time-controlled high idle

Tire radius

Transmission disengagement

Transmission oil filter

Transmission oil level’

Transmission oil pressure

Transmission oil temperature

Transmission protection

Transmission slipping

Travelling speed

Turbine speed

Turbocharger, description

Unit pump, description

Unit pumps

Valves, description

Vehicle control unit V-ECU, description

Vibration damper, description

Vibration damper, description1

Voltage feed E-ECU, I-ECU, V-ECU

Voltage feed for sensors

Warming of hydraulic oil

Washer fluid level

Water in fuel

Wear indicator, description

Wiping during and after washing

Working on the electrical system of the machine

Diagrams

- Circuit list

Explanations to hydraulic diagram

Hydraulic diagram, complete fig1

Hydraulic diagram, complete

Hydraulic diagram, fan, brake system fig 1

Hydraulic diagram, fan, brake system

Hydraulic diagram, reversible fan, brake system fig1

Hydraulic diagram, reversible fan, brake system

Hydraulic diagram, steering fig1

Hydraulic diagram, steering with CDC and secondary steering 1 fig1

Hydraulic diagram, steering with CDC and secondary steering 1

Hydraulic diagram, steering with CDC and secondary steering fig1

Hydraulic diagram, steering with CDC and secondary steering

Hydraulic diagram, steering

Hydraulic diagram, working hydraulics, differential lock fig1

Hydraulic diagram, working hydraulics, differential lock, BSS fig1

Hydraulic diagram, working hydraulics, differential lock, BSS, attachment lock, 3rd 4th function fig1

Hydraulic diagram, working hydraulics, differential lock, BSS, attachment lock, 3rd 4th function

Hydraulic diagram, working hydraulics, differential lock, BSS

Hydraulic diagram, working hydraulics, differential lock

Wiring diagram 1

Wiring diagram 2

Wiring diagram 3

Wiring diagram 4

Wiring diagram 5

Wiring diagram 6

Wiring diagram 7.1

Wiring diagram 7.2

Wiring diagram 8

Wiring diagram 9

Wiring diagram 9B

Wiring diagram 10

Wiring diagram 11

Wiring diagram 12

Wiring diagram 13

Wiring diagram 15B

Wiring diagram 16

Wiring diagram 17 Updateted CDC

Wiring diagram 17

Wiring diagram 18

Wiring diagram 19

Wiring diagram 19C

Wiring diagram 20

Wiring diagram 21B

Wiring diagram 21C

Wiring diagram 22

Wiring diagram 23

Wiring diagram 24

Wiring diagram 25

Wiring diagram 26

Wiring diagram 27

Wiring diagram 28

Wiring diagram 29

Wiring diagram 30

Wiring diagram 31

Wiring diagram 32

Wiring diagram 33

Wiring diagram 34

Wiring diagram 35

Wiring diagram 101

Wiring diagram 102

Wiring diagram 103

Wiring diagram 107

Installation Instructions

- 3rd hydraulic function retaining function

AC Electric fan

Attachment lock

Care track 1

Care track

Engine heater 120V 1250W

Front working lights

Heat insulation kit

Lever steering

Mounting kit, wide seat

Oil-bath air cleaner

Radio kit, right

Return to dig

Reversible fan

Single lever control

Tail lamp guard

Repair

- AC software-controlled, description

Accumulator, checking (removed)

Air conditioning, checking performance

Air conditioning, description

Air conditioning, troubleshooting, software-controlled ATC

ATC, description

Attachment bracket cylinder, reconditioning

Attachment locking hydraulic cylinder (vision-optimised bracket), replacing

Battery, changing

Battery, charging

Boom suspension system, accumulator, changing

Boom Suspension System, component description

Boom suspension system, hydraulic oil pressure in accumulators, depressurizing

Boom Suspension System, pressure-reducing valve, adjusting

Boom suspension system, reconditioning accumulator

Boom suspension system, test drive with load

Boom Suspension System, troubleshooting

Boom, description

Brake discs, changing

Brake discs, checking wear

Brake system, bleeding

Brake system, checking hydraulic function

Brake system, retardation, checking function

Cab suspension, description

Cab, description

Cab, installing

Cab, removing

Central lubrication system, description

Checking LS-pressure for pump 1 (P1) and pump 2 (P2)

Components

Compression test

Coolant pump, replacing

Cooling fan hydraulics, funktion check

Cooling fan motor, replacing

Counterweight, replacing

Crankshaft, replacing front oil seal 1

Crankshaft, replacing front oil seal

Differential lock

Discarded accumulators

Drive shaft, changing

Engine ECU, removing

Engine hood, installing 1

Engine hood, installing

Engine hood, removing 1

Engine hood, removing

Engine mounting, front, replacing.

Engine, installing 1

Engine, installing

Engine, removing 1

Engine, removing 2

Evaporator in air conditioning system, cleaning

Fan motor, changing

Feed pump, checking feed pressure 1

Filler grease filter, cleaning (optional equipment)

Final drive

Flexible hose, replacing

Flow control Pump 1 (P1) and Pump 2 (P2)

Foot brake pedal, adjusting angle and pedal clearance

Foot brake valve removed, reconditioning

Front axle, installing

Front axle, removing

Fuel control valve (FCV), checking

Fuel control valve (FCV), replacing

Fuel feed pressure, checking

Fuel filter, checking

Fuel rail pressure sensor, replacing

Fuel system, bleeding 1

Fuel system, bleeding

Function test, secondary steering

Gear selector valve, measuring resistance of solenoids

Gear selector valve, removing and installing 1

Gear selector valve, removing and installing

General description

Heat control valve, changing

Heater core, changing

High pressure fuel pump, checking

High pressure fuel pump, replacing

Hub, changing seal

Hub, changing seal1

Hub, changing seal2′

Hydraulic attachment lock (software-controlled), description

Hydraulic attachment lock with raised servo pressure, description

Hydraulic oil tank, description

Hydraulic oil tank, vacuum-pumping, connecting and disconnecting pump

Hydraulic pump, checking and adjusting max working pressure

Hydraulic pump, checking and adjusting max working pressure1

Hydraulic pump, checking and adjusting standby pressure

Hydraulic system, bleeding

Hydraulic system, description

Implemental attachment hydraulic cylinder, replacing

Injector, replacing

Injectors, replacing all

Lever steering CDC, checking steering signals

Lever steering, adjusting steering speed

Lever steering, checking and adjusting control valve

Lifting cylinder 1

Lifting cylinder

Lubrication cycle, description

Maintenance service, daily

Maintenance service, every 50 hours

Maintenance service, every 250 hours

Maintenance service, every 500 hours

Maintenance service, every 1000 hours

Maintenance service, every 2000 hours

Maintenance service, every 3000 hours

Maintenance service, every 4000 hours

Maintenance service, every 6000 hours

Measuring axial and radial play, rear axle mounting

MS.Internal.Documents

Oil pan, resealing

Parking brake, mechanical release

Planetary gear

Precharge pressure in accumulators, checking and adjusting

Pressure in circuit, checking and adjusting

Pressure monitor, description

Pressure relief valve (PRV), checking

Pressure relief valve (PRV), replacing

Pump 3 (P3) Cooling fan pump Brake pump. Cooling fan, checking max. rpm

Pump 3 (P3) Fan pump Brake pump Fan, check max pressure

Pump 3 (P3) standby pressure, checking

Pump 3 (P3) standby pressure, checking1

Pump unit, replacing

Radiator, installing 1

Radiator, installing

Radiator, removing 1

Radiator, removing

Rear axle, installing

Rear axle, removing

Return To Dig, component position

Reversible cooling fan, funktion check

Sensor for differential lock, adjusting

Servo pressure, checking and adjusting

Servo valve, operating controls, adjusting

Servo valve, replacing

Shift valve, checking

Shock valve lift function, checking

Shock valve, tilt function, checking

Stall speed, checking

Stand-by pressure Pump 1 (P1) and Pump 2 (P2), checking and adjusting

Steer cylinder, left, changing

Steering pressure, checking and adjusting

Steering valve, reconditioning (removed)

Steering valve, replacing

Thermostat, replacing 1

Thermostat, replacing

Torque converter, removing, installing

Towing

Transmission oil pressure, checking

Transmission oil pressure, checking1

Transmission oil pressure, checking2

Transmission oil pressure, checking3

Transmission, installing

Transmission, removing

Turbocharger, inspection

Valves, adjusting 1

Valves, adjusting

Viscous cab suspension, changing one unit

Warranty inspection 100 hours

Warranty inspection 1000 hours

Wheel, removing and installing

Working hydraulic system, component location

Working hydraulic system, description

Working hydraulics, troubleshooting

Working pressure Pump 1 (P1) and Pump 2 (P2), checking and adjustment

Safety

- CE-marking, EMC-directive

Checklist after a fire or heat exposure

Decontamination

Environmental handling for the future

Environmentally hazardous fluids

Environmentally safe handling

Health hazards with paint, plastics and rubber

Safety concerns everybody!

Safety when handling accumulators

Safety when handling oils and fuel

Safety when handling the machine

Safety when using lifting equipment

Safety when working on hydraulic systems

Safety when working with air conditioning refrigerant

Safety when working with batteries

Some simple rules regarding tyre handling

Starting with booster batteries

Waste handling

Working in environmentally contaminated areas

Working under raised boom

Service Bulletins

- AC compressor, fill with oil

Action to be taken in case of abnormal lubricating oil consumption

Alternative lubricants for axles with wet brakes

Amendments in Service Manual Engine, D10B; Drive Axle, AWB 40B and Drive Axle, AWB 41 AWB 50

Automatic greasing systems of foreign manufacture

Automatic shifting (APS)

Automatic transmission lubricants

Battery and alternator test procedure

Brake return spring moved

Cable harness connector, engine

CareTrack Telematics system

D- arm cracks

D6-D7 Exhaust gas leakage into the cooling system

Decoding of radio

Delayed idle as adjustable parameter

Detecting leaks with inspection lamp

Diesel fuels – quality and function

Discontinued recommendation for usage of anti-corrosion agent in cooling system

ECU, functional check

Electrical air condition condenser fan

Engine oil requirements

Engine radiator

Engine software release W0647 for L60E-L120E Tier 2Stage 2

Exhaust insulation

Exhaust leakage into fuel system D6-D7

Final software version 2004 W35 for hardware 11184401 V-ECU

Fork arms, information warranty matters, altered procedures

Fuel in engine oil

Fuel leak

Fuel sampling, method

Gear shifting, HTE-series transmissions

Greasing of hydraulic pump drive shaft

Hydraulic power control

Improved attachment of fan grid

Improved hour recorder

Improved oil cooler housing

Improved turbo oil return pipe and clamp

Instructions for crack in lifting frame

Instructions for drilling in ROPS structure

Instructions for shielded metal arc welding

Intercooler air duct, improved hose and seals

Leakage at engine oil pump gasket

Leakage of axle oil

Limitation, TP-linkage

Loose seat base

Monitoring function for high rail pressure changed on Tier3 engines

MS.Internal.Documents

New alternator anchorage

New BSS valve

New camshaft sensor in new position

New CareTrack W-ECU2

New coolant

New engine oil level sensor

New engine software medium platform

New hardware for E-ECU

New hardware for V-ECU and software version R 2004 w 51

New hydraulic oil filter

New I-ECU introduction

New rear axle

New screws and washers for intercooler bracket

New sensor for accelerator pedal

New software for E-models

New starter switch

Non – VCE buckets and attachments

Non-return valve on the fuel return hose

Oil analyses

Oil leakage, crankshaft (oil pump side) D4D-D7D

Oil sump

Oils for Volvos wheel loaders equipped with AWB axles (Axle Wet Brakes)

O-rings with improved heat resistance

Parking brake solenoid valve

Position of orifice within the hydraulic pump compensator

Quality measures for V-ECU

Quality of illustrations in technical reports

Raising and supporting machines (up to and including the E models)

Recommendations for Oil Sampling Intervals

Reinforced screw stud

Repair instructions for attachments

Repair instructions for turbo wastegate linkage

Replaced fuel level sensor

Replacement of throttle pedal pivot pin

Replacement of turbocharger

Replacing bracket and drive belt for AC-compressor

Replacing operator seat shock absorber

Replacing parking brake seal

Replacing unit pump on engines D6D and D7D

Reporting of product misuse & near-miss report

Reports

Seals

Sensor, check

Service solution, separate belts

Specifications, stall speed

Technique and procedures when replacing valve cover gasket

Tyres, various types

Volvo Product incident accident report & Interview Form

Water separator improvement

Work instruction for campaign WLO1203 – Reinforcement of rear frame’s center hinge bearing

Special tool catalog

- General

Index

Hooks

1. Enviroment and Safety equipment

2. Measuring equipment

3. Tightening and Loosening tools

4. Lifting equipment

5. Pullers and Pressing equipment

6. Drifts

7. Guide pins and Guide sleeves

8. Pliers

9. Fixtures

10. Tech Tool

11. Spare parts

Time Guide Currrent generation

Time Guide Old generation

Time Guide Previous generation

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution