- No products in the cart.

Volvo G946C Motor Grader Service and Repair Manual PDF

Size: 221.08 MB

Language: English

Make: Volvo

Machine: Motor Grader

Document: Service and Repair Manual, Hydraulic Diagram, Electrical Diagram

Model: Volvo G946C

US $50

Brands:

Volvo

Description

Volvo G946C Motor Grader Service and Repair Manual PDF

Size: 221.08 MB

Language: English

Make: Volvo

Machine: Motor Grader

Document: Service and Repair Manual, Hydraulic Diagram, Electrical Diagram

Model: Volvo G946C

Page: 5217 Pages

Detail Contents:

1 Volvo G946C

Description

- 2 Engine with Mounting & Equipment

3 Elect. Warning, Information, Instruments

All Wheel Drive (AWD) system, description

Differential lock, description

Hydraulic brake system, description

Joystick control system, description

Joystick control, component locations

Secondary steering, description

Transmission, description1

Transmission, description2

Windows, general

Diagrams

- Component list, Diodes

Component list, fuses

Component list, PWM valves

Component list, relays

Component list, resistors

Component list, sensors

Component list, Solenoid valves

Component list, Switches

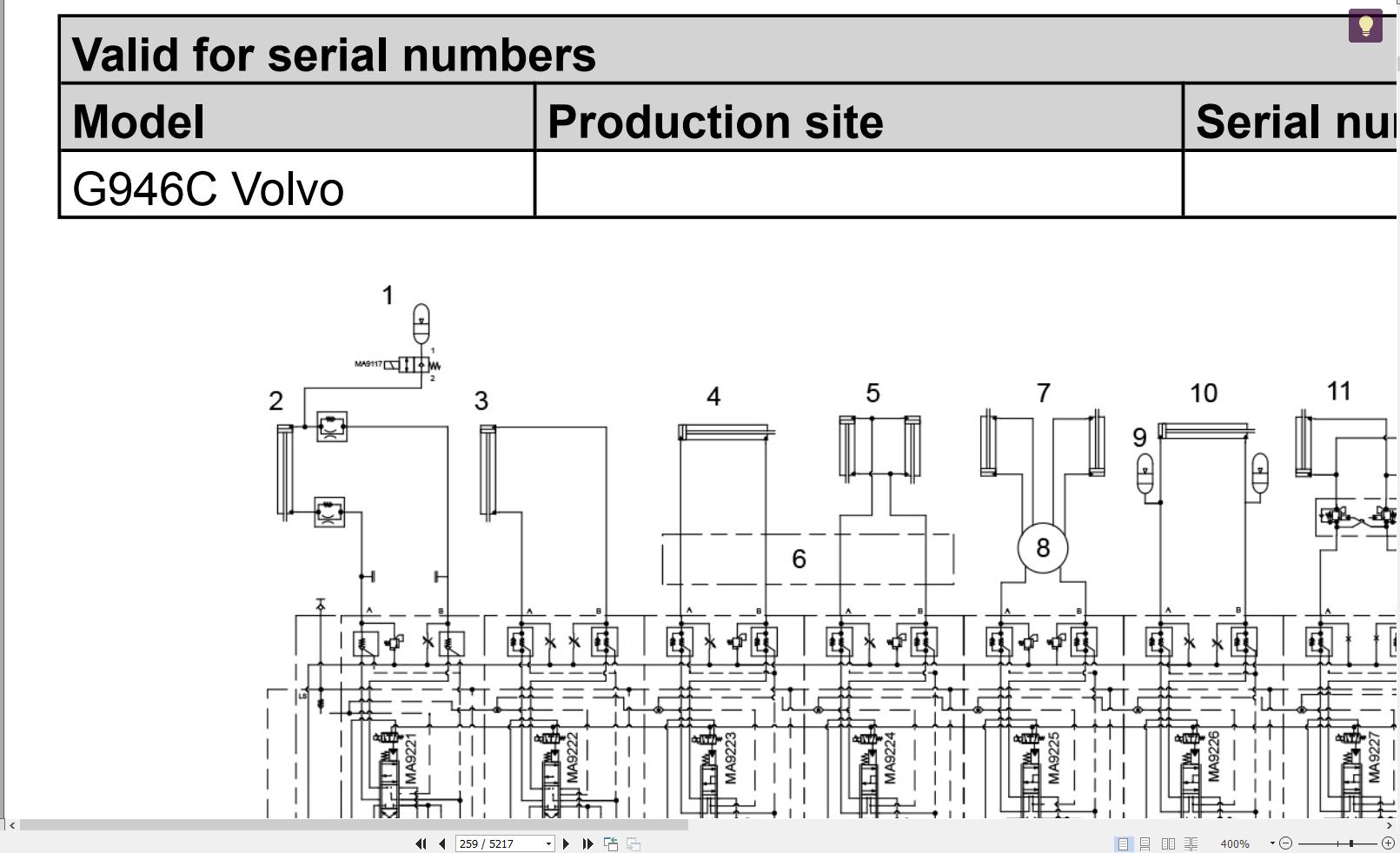

Hydraulic diagram 1

Hydraulic diagram 2

Hydraulic diagram 3

Hydraulic diagram, component locations1

Hydraulic diagram, component locations2

Wiring diagram 1

Wiring diagram 2

Wiring diagram 3

Wiring diagram 4

Wiring diagram 5

Wiring diagram 6

Wiring diagram 7

Wiring diagram 8

Wiring diagram 9

Wiring diagram 10

Wiring diagram 11

Wiring diagram 12

Wiring diagram 13

Wiring diagram 14

Wiring diagram 15

Wiring diagram 16

Wiring diagram 17

Wiring diagram 18

Wiring diagram 19

Wiring diagram 20

Wiring diagram 21

Wiring diagram 22

Wiring diagram 23

Wiring diagram 24

Wiring diagram 25

Wiring diagram 26

Wiring diagram 27

Wiring diagram 28

Wiring diagram 29

Wiring diagram 30

Wiring diagram 31

Wiring diagram 32

Wiring diagram 33

Wiring diagram 34

Wiring diagram 35

Wiring diagram 36

Wiring diagram 37

Wiring diagram 38

Wiring diagram 39

Wiring diagram 40

Wiring diagram 41

Wiring diagram index

Installation Instruction

- 2 Bank control levers kit, installing new

Air compressor kit, installing new

Auxiliary 2 bank valve front mount kit, installing new

Auxiliary hydraulic circuit to the right side, installing new

Auxiliary hydraulics cap plugs, installing new

Auxiliary hydraulics enable switch with float, installing new

Auxiliary hydraulics enable switch without float, installing new

Cab mounted front work lights kit, installing new

Cab mounted rear work lights kit, installing new

Cab mounted rear work lights kit, installing new1

Double washer pumps and bottle, installing new

Electrical auxiliary valve 2 bank – front mount kit, installing new

Electrical auxiliary valve 2 bank – front mount kit, installing new1

Front window one arm wiper washer for low cab, installing new

Front window pantograph wiper washer for high cab, installing new

Heated outside mirrors kit, installing new

Hydraulic circuits to front right side

Hydraulic circuits to front right side1

Hydraulic circuits to front right side2

Mid mount scarifier, installing

Rear window one arm wiper washer for low cab, installing new

Rear window pantograph wiper washer for high cab, installing new

Rotating beacon, installing new

Strobe light, installing new

Support arch, installing

Technology ready grade slope controls with accumulators, installing new

Technology ready grade slope controls without accumulators, installing new

Repair

- 0 General

1 Standard Parts, Service

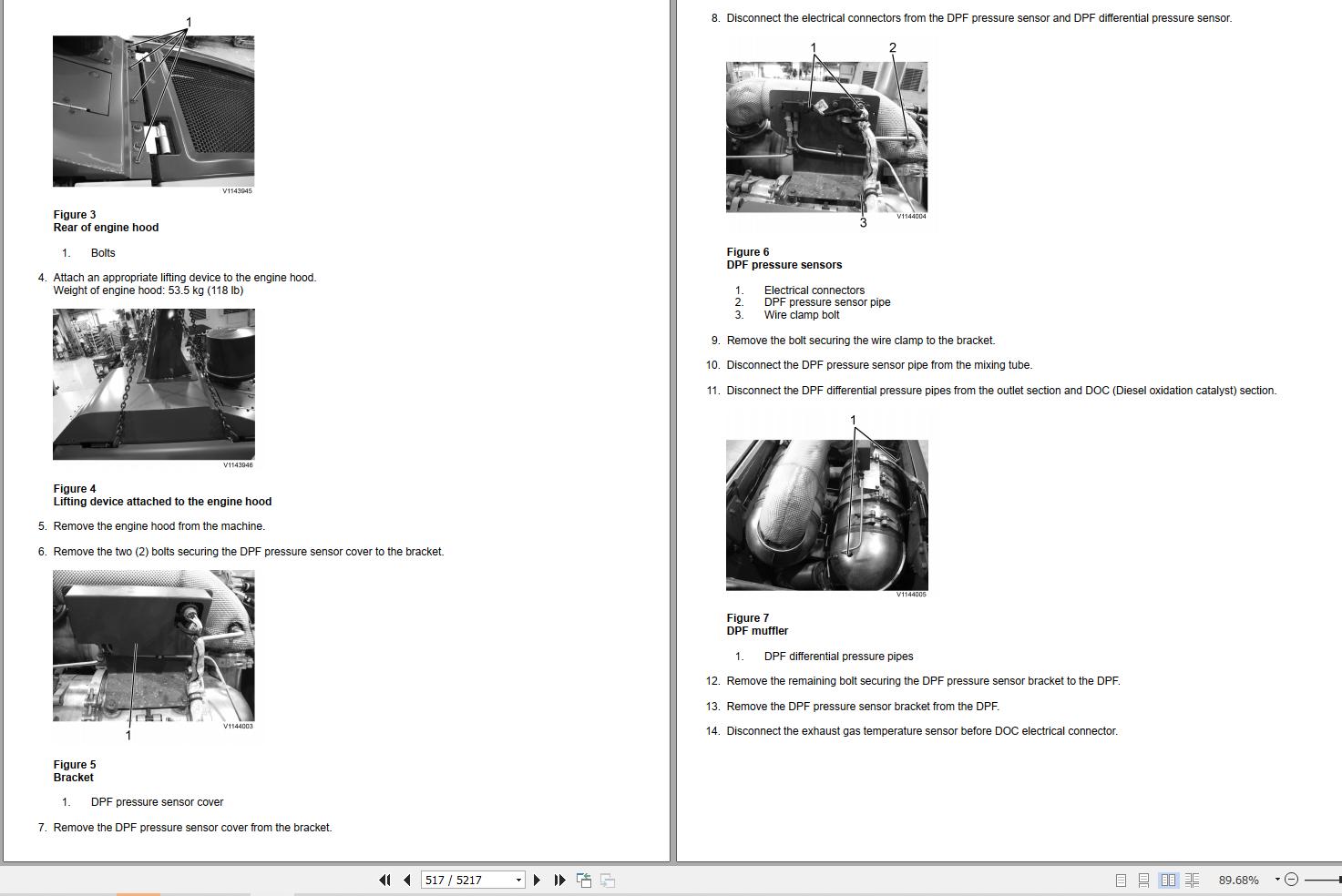

2 Engine with Mounting & Equipment

3 Elect. Warning, Information, Instruments

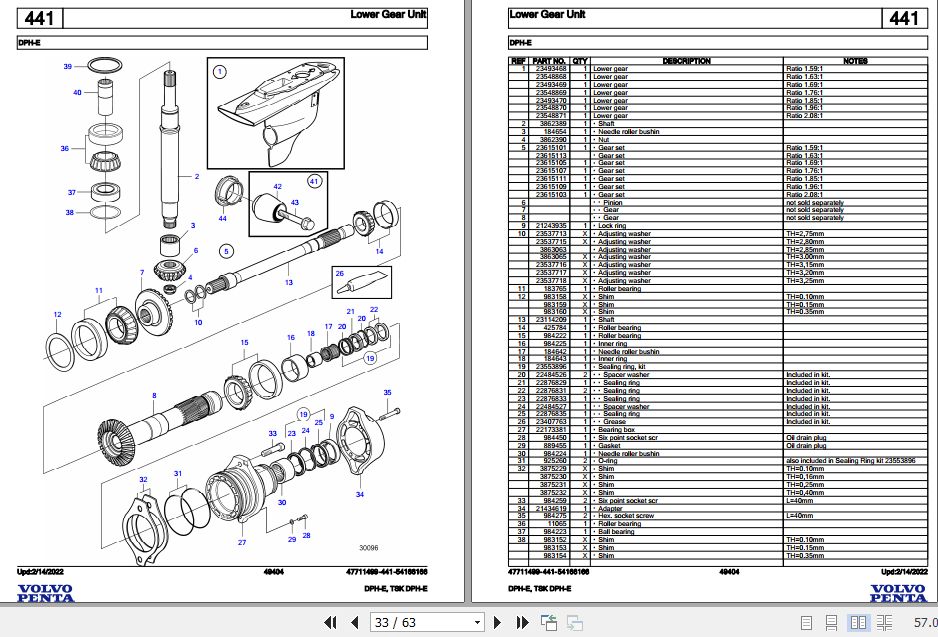

4 Power Transmission

5 Brake

6 Steering

7 Frame, Springs, Damping, Axle Suspension, Wheel-Track Unit

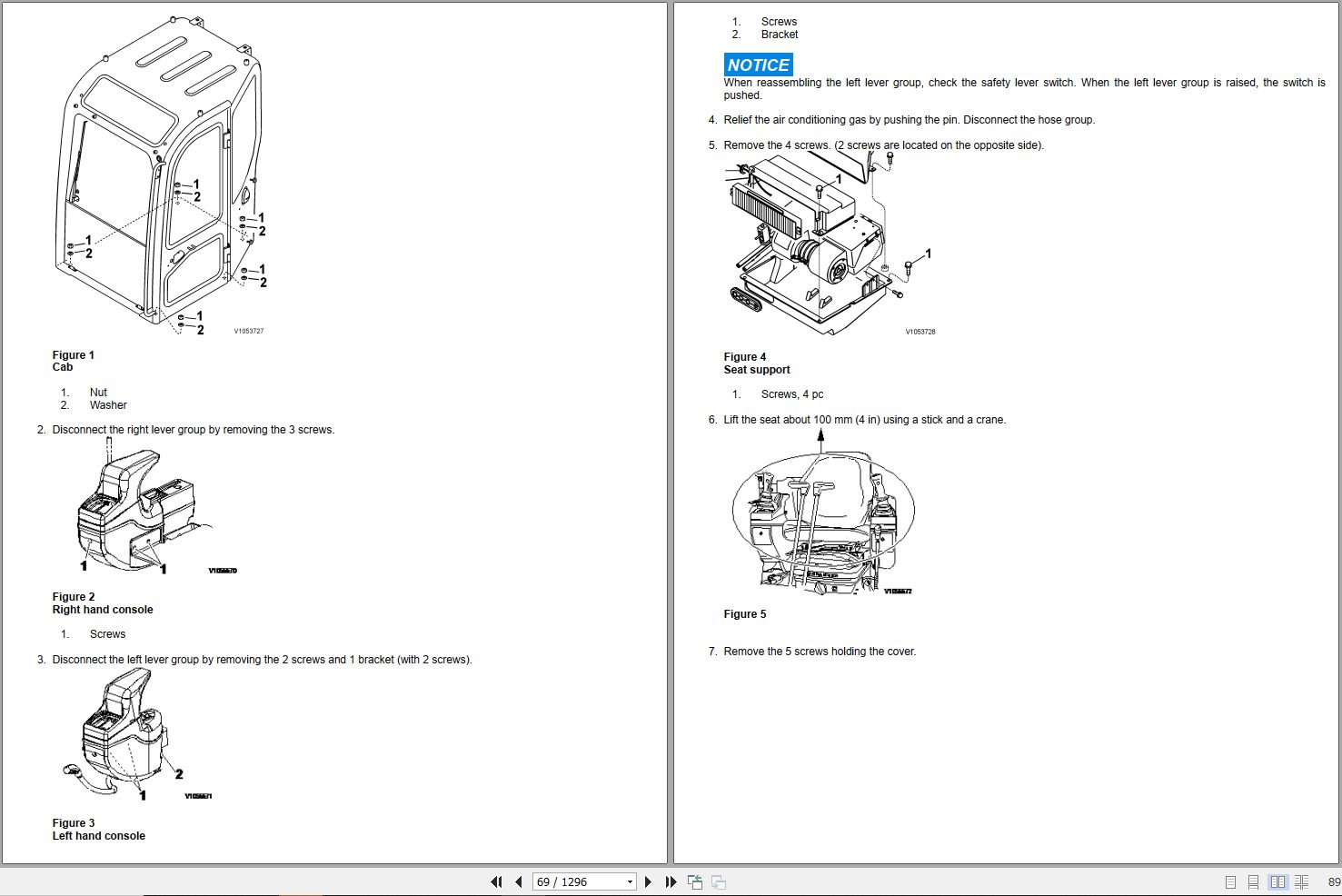

8 Machinery House, Cab, Exterior Trim Parts

9 Hydraulic, Digging, Handling, Grading Equipment, Misc

Safety

- A few simple safety rules

Before operating

Before service, read

CE-marking, EMC-directive

Charging batteries

Checklist after a fire or heat exposure

Cleanliness

Decontamination

Electrical system

Environment

Environmental handling for the future

Environmentally hazardous fluids

Environmentally safe handling

Fire prevention measures

General

Health hazards with paint, plastics and rubber

Safety concerns everybody!

Safety rules when servicing

Safety when handling oil and fuel

Safety when lifting and supporting complete machine

Safety when using lifting equipment

Safety when working on hydraulic systems

Safety when working with air conditioning refrigerant

Safety when working with batteries

Service position

Some simple rules regarding tyre handling

Working in environmentally contaminated areas

Service Bulletins

- Articulation cylinder front mounting lug

Biodiesel fuel for Volvo CE

CareTrack, new software version 2008w6

Check method on engine oil consumption

D8H, D8J New belt tensioner

EGR temperature sensor

Fuel sampling, method

How to update software when programming fails

Hydraulic oil dye

Main implement and steering pump load sense filter screen

New axle breather kit

New fastener assortment

New G900C Motor Grader

New hydraulic brake system information

New radio bracket

New TechTool VCADS Pro interface

Oil dipstick pushed out of the guide tube

Parallel Ripper hydraulic circuit performance

Portable refillable O-ring kits

Recommendations for Oil Sampling Intervals

Reporting of product misuse & near-miss report

Reports

Serial number location on machine components

Software information for CEA2+ products

Software release summary for C-series models

Transmission breather

Transmission pressure test procedure and inspection sheet

Volvo Product incident accident report & Interview Form

Special Tools, Misc

- Special Tools Recommendations Motor Grades

GRD G700B LabourTimeGuide

RM Compaction ABG Time Guide

RM Compaction Time guide

RM Paving Systems ABG Time Guide

Service Programme

Special tool Manual

Special Tools Recommendations for G940C

Time Guide Currrent generation

Time Guide Old generation

Time Guide Previous generation

Specifications

- Accumulator, specifications

AdBlue® DEF

Air conditioning, specifications

Air conditioning, tightening torques

Air distribution, specifications

All Wheel Drive hydraulic motor, specifications

All Wheel Drive hydraulic pump, specifications

Alternative fuels

Articulation, tightening torques

Attachment, tightening torques

Axle, tightening torques

Blade lift system lock pin cylinder solenoid valve, specifications

Blade lift system, tighten torques

Brake accumulator, specifications

Brake system, specifications

Brake system, specifications1

Brake system, tightening torques

Cab, tightening torques

Circle and drawbar, specifications

Circle and drawbar, tightening torques

Cooling fan, tightening torques

Cooling system, specifications

Cooling system, tightening torques

E-6000

E-6001

EGR system, tightening torques

Engine, specifications

Engine, tightening torques1

Engine, tightening torques2

Fan motor, specifications

Fan pump, specifications

Fuel system, specifications

Fuel system, tightening torques

Fuel, lubricant and filling capacities

Hydraulic connections, tightening torques

Hydraulic oil filters, tightening torques

Hydraulic system, tightening torques

Inlet and exhaust system, specification

Inlet and exhaust system, tightening torques

Lubrication system, specifications

Lubrication system, tightening torques

Main implement and steering hydraulic pump, specifications

Operator seat, tightening torques

Pump drive, tightening torques

Recommended lubricants

Secondary steering pump, specifications

Steering valve, specifications

Steering, specification

Steering, tightening torques

Thread locking compound, application specifications

Tightening torque, specifications

Tightening torque, specifications2

Transmission, specifications1

Transmission, specifications2

Transmission, tightening torques

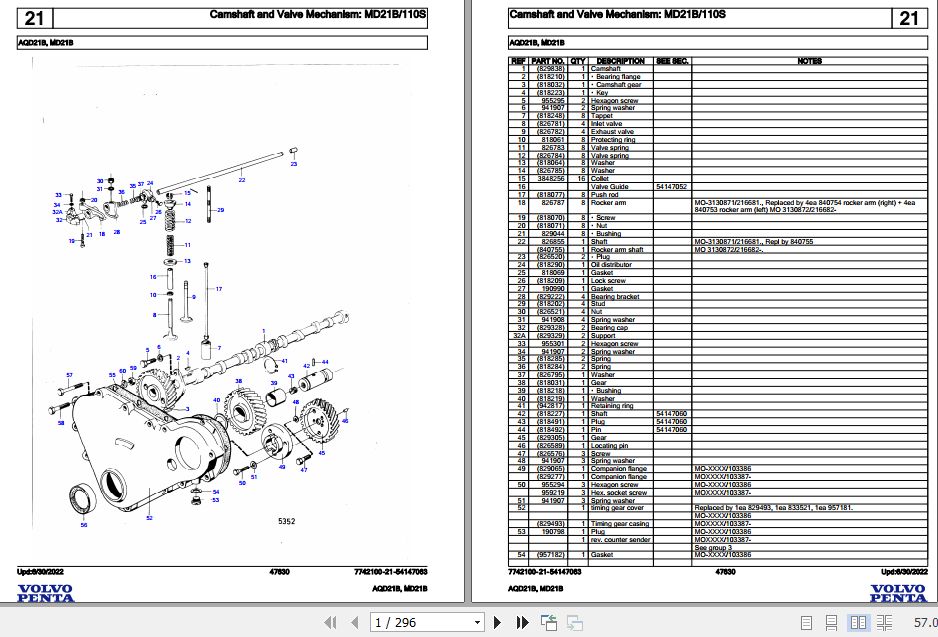

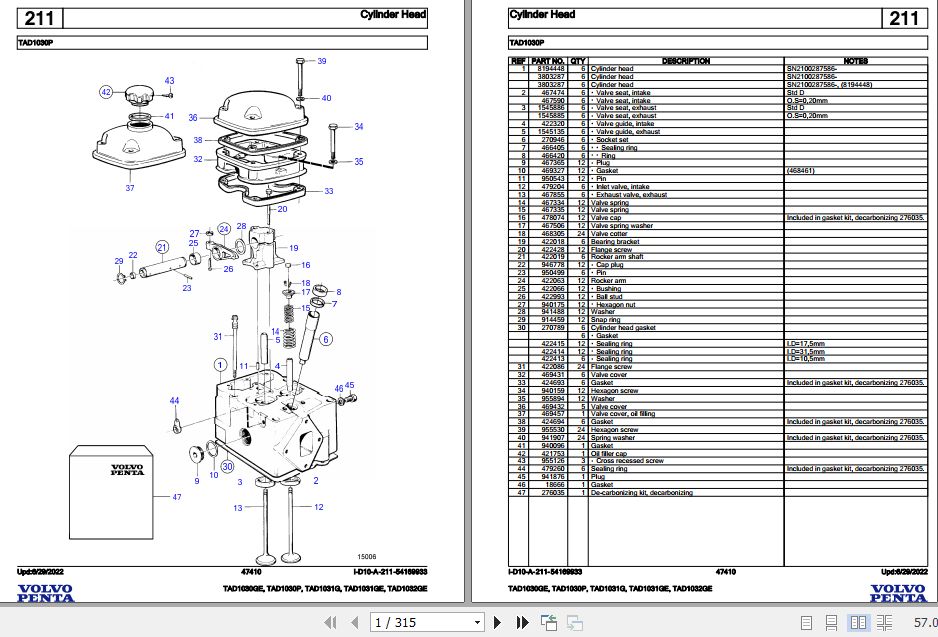

Valve mechanism, specifications

Valve mechanism, tightening torques

Wheels, specifications

Wheels, tightening torques

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution