- No products in the cart.

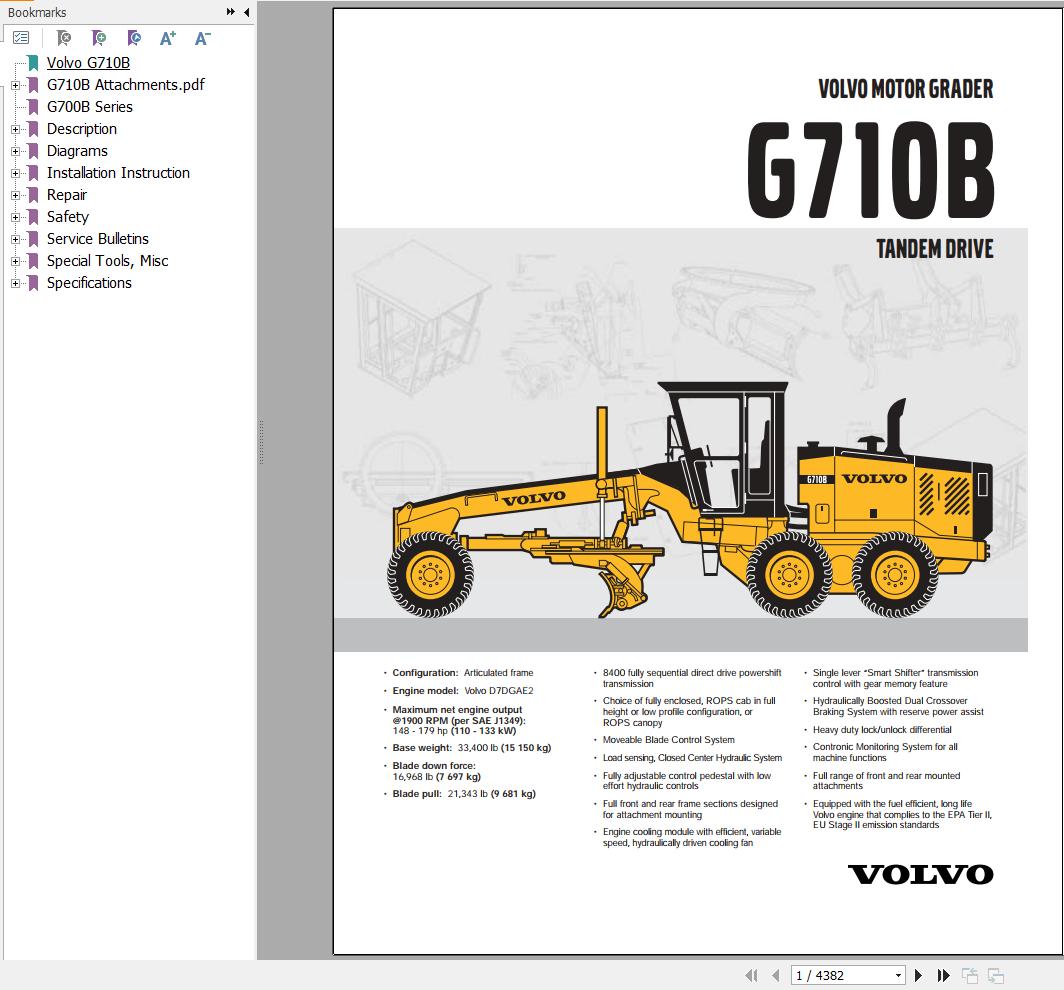

Volvo G710B Motor Grader Service and Repair Manual PDF

Size: 73.29 MB

Language: English

Make: Volvo

Machine: Motor Grader

Document: Service and Repair Manual, Hydraulic and Electrical Diagrams

Model: Volvo G710B

US $50

Brands:

Volvo

Description

Volvo G710B Motor Grader Service and Repair Manual PDF

Size: 73.29 MB

Language: English

Make: Volvo

Machine: Motor Grader

Document: Service and Repair Manual, Hydraulic and Electrical Diagrams

Model: Volvo G710B

Page: 4382 Pages

Detail Contents:

Volvo G710B

G710B Attachments.pdf

- Dozer Blade

Mid Mount Scarifier

Push Block

Rupper Scarifier

G700B Series

Description

- Accelerator decelerator pedal

Air cleaner

Alternator, description

Articulation hinge – Preparation for disassembly

Articulation hydraulics Figure 1

Articulation hydraulics Figure 2

Articulation hydraulics

Articulation Indicator – Setup and Adjustment Figure 3

Articulation Indicator – Setup and Adjustment

Articulation Indicator – Setup and Adjustment1 Figure 1

Articulation Indicator – Setup and Adjustment1 Figure 2

Articulation Indicator – Setup and Adjustment1

Automatic control blocking function

AWD electrical system Figure 1

AWD electrical system Figure 2

AWD electrical system Figure 3

AWD electrical system

AWD hydraulic system Figure 1

AWD hydraulic system Figure 2

AWD hydraulic system Figure 3

AWD hydraulic system Figure 4

AWD hydraulic system Figure 5

AWD hydraulic system Figure 6

AWD hydraulic system Figure 7

AWD hydraulic system Figure 8

AWD hydraulic system Figure 9

AWD hydraulic system Figure 10

AWD hydraulic system Figure 11

AWD hydraulic system

Basic operational checks

Battery box

Battery, charging

Battery, charging1

Cab air distribution

Cab air distribution1

Cable; Battery isolation switch

Camshaft – D10B, description

Circle operation Figure 1

Circle operation Figure 2

Circle operation Figure 3

Circle operation Figure 4

Circle operation Figure 5

Circle operation Figure 6

Circle operation

circle turn valve

Compensator Valve Pressure Setting – Checking

Connecting rod, D7D Figure 1

Connecting rod, D7D

Cooling system – D7D engine, description

Crankshaft and vibration damper, D10B Figure 1

Crankshaft and vibration damper, D10B

Crankshaft, D7D

Cylinder block – D10B, description

Cylinder head – D10B, description

Cylinder liner; piston, D7D description

Cylinder liner; piston, D10B Figure 1

Cylinder liner; piston, D10B

Cylinder liners, D10B description

Description AC

Description and operation, engine clutch Figure 1

Description and operation, engine clutch Figure 2

Description and operation, engine clutch

Description Battery

Description Brakes Figure 1

Description Brakes

Description Drawbar Figure 1

Description Drawbar

Description Figure 1

Description Figure 2

Description Figure 3

Description Figure 6

Description Figure 7

Description Figure 11

Description Figure 12

Description Frame Figure 1

Description Frame

Description Hydraulic Brake Figure 1

Description Hydraulic Brake Figure 2

Description Hydraulic Brake Figure 3

Description Hydraulic Brake Figure 4

Description Hydraulic Brake Figure 5

Description Hydraulic Brake Figure 6

Description Hydraulic Brake Figure 7

Description Hydraulic Brake Figure 8

Description Hydraulic Brake

Description hydraulic

Description Instrument panel console Figure 1

Description Instrument panel console Figure 2

Description Instrument panel console Figure 3

Description Instrument panel console

Description MBCS Figure 1

Description MBCS Figure 2

Description MBCS

Description mechanical equipment

Description of tests

Description Parking Brake Figure 1

Description Parking Brake Figure 2

Description Parking Brake

Description Steering Figure 1

Description Steering

Description Supplementary steering Figure 1

Description Supplementary steering Figure 2

Description Supplementary steering

Description Wheel lean Figure 1

Description Wheel lean

Description, 8400 transmission

Description, AWD system Figure 1

Description, AWD system Figure 4

Description, AWD system Figure 5

Description, AWD system Figure 6

Description, AWD system Figure 7

Description, AWD system

Description, clutch master cylinder and booster Figure 1

Description, clutch master cylinder and booster Figure 2

Description, clutch master cylinder and booster

Description, D7D

Description, D10B

Description, G780B – DR final drive

Description, SR final drives

Description

Description1

Description2

Description3

Diagnostic software

Differential Lock, G710B – G746B Figure 1

Differential Lock, G710B – G746B

Differential Lock, G780B Figure 1

Differential Lock, G780B

Direction indicator; turn signal

Electric air – preheater

Electrical symbols and designations

Engine timing gear – D10B, description Figure 1

Engine timing gear – D10B, description

Exhaust system – D7D engine

Exhaust system – D10B engine

External warning system

Fuel feed pump – D10B, description

Fuel flow, D10B Figure 1

Fuel flow, D10B Figure 2

Fuel flow, D10B

Fuel shut-off valve, D10B

Fuel system – D7D, description

Fuel system – D10B, description

Fuel system components, D10B Figure 1

Fuel system components, D10B

Function Figure 1

Function Hydraulic equipment Figure 1

Function Hydraulic equipment Figure 2

Function Hydraulic equipment

Function

Function1 Figure 1

Function1 Figure 2

Function1

General description

General description1

General lighting

General, Lubrication oil pump D7D Figure 1

General, Lubrication oil pump D7D

General

General1

Grader setup instructions

Hand Throttle Figure 1

Hand Throttle

Hydraulic components, location

Hydraulic pump Figure 1

Hydraulic pump

hydraulic swivel joint Figure 1

hydraulic swivel joint Figure 2

hydraulic swivel joint

Ignition switch

Injection pump – D10B, description Figure 1

Injection pump – D10B, description Figure 2

Injection pump – D10B, description

Injection system – D7D, E-ECU overview Figure 1

Injection system – D7D, E-ECU overview Figure 2

Injection system – D7D, E-ECU overview Figure 3

Injection system – D7D, E-ECU overview

Injectors – D10B, description Figure 1

Injectors – D10B, description

Intended use

Intercooler, D10B

Jump-start procedure

Lighting, front

Lighting, interior

Lighting, rear

Lighting, side

Lock unlock function

Lubrication circuit

Lubrication oil circuit, D7D engine– Models G710B to G730B Figure 1

Lubrication oil circuit, D7D engine– Models G710B to G730B

Lubrication system – D10B, description Figure 1

Lubrication system – D10B, description Figure 2

Lubrication system – D10B, description

Main control valve section Figure 1

Main control valve section

Neutral start relay

Oil trap – D10B, description

Operating principle AC Figure 1

Operating principle AC

Operation, G780B DR final drive Figure 1

Operation, G780B DR final drive

Operation, SR final drive Figure 1

Operation, SR final drive

Operation

Overflow valve, D10B

Overview – G710B to G746B Figure 1

Overview – G710B to G746B Figure 2

Overview – G710B to G746B

Overview – G780B Figure 1

Overview – G780B

Overview Brakes Figure 1

Overview Brakes Figure 2

Overview Brakes

Parking brake intensifier Figure 1

Parking brake intensifier

Parking brake valve assembly Figure 1

Parking brake valve assembly Figure 2

Parking brake valve assembly

Preheating coil, D10B

Principle of operation, main hydraulic pump Figure 1

Principle of operation, main hydraulic pump

Principle of operation, pressure compensator control Figure 1

Principle of operation, pressure compensator control Figure 2

Principle of operation, pressure compensator control Figure 3

Principle of operation, pressure compensator control

Repairing hydraulic system

Special tools

Starting system, general description

Storage

Tandem oil disc brake oils

Torsional vibration damper, D7D Figure 1

Torsional vibration damper, D7D

Towing

Transmission ECU and shifter assembly Figure 1

Transmission ECU and shifter assembly Figure 2

Transmission ECU and shifter assembly Figure 3

Transmission ECU and shifter assembly

Transmission hydraulic circuit and operation Figure 1

Transmission hydraulic circuit and operation

Transmission oil circuit and operation Figure 1

Transmission oil circuit and operation Figure 4

Transmission oil circuit and operation Figure 5

Transmission oil circuit and operation Figure 6

Transmission oil circuit and operation

Transporting the machine

Valve mechanism – D10B, description Figure 1

Valve mechanism – D10B, description

Valves – D7D, description

VHP (Variable Horsepower)

Voltage regulator

Water trap, D10B

Diagrams

- Auxiliary control valves – Sheet 5 Figure 1

Auxiliary control valves – Sheet 5

Auxiliary load sense shuttle valve Figure 1

Auxiliary load sense shuttle valve

Brake circuit hydraulic schematic Figure 1

Brake circuit hydraulic schematic

Climate control unit electrical schematic Figure 1

Climate control unit electrical schematic

Counterbalance valve for attachments Figure 1

Counterbalance valve for attachments Figure 2

Counterbalance valve for attachments

Cylinder head – D7D, description Figure 1

Electrical schematic Figure 1

Electrical schematic Figure 2

Electrical schematic

Electrical schematic1 Figure 1

Electrical schematic1

Hydraulic diagram Figure 1

Hydraulic diagram

Main hydraulic schematic – sheet 1 Figure 1

Main hydraulic schematic – sheet 1

Main hydraulic schematic, EEC – Sheet 3 Figure 1

Main hydraulic schematic, EEC – Sheet 3

Main hydraulic schematic, EEC float valves – Sheet 4 Figure 1

Main hydraulic schematic, EEC float valves – Sheet 4

Main hydraulic schematic, float valves – Sheet 2 Figure 1

Main hydraulic schematic, float valves – Sheet 2

Secondary steering hydraulic schematic Figure 1

Secondary steering hydraulic schematic

Single attachment valve with relief (EEC) Figure 1

Single attachment valve with relief (EEC)

Steering hydraulic schematics Figure 1

Steering hydraulic schematics

Wheel lean hydraulic schematic Figure 1

Wheel lean hydraulic schematic

Wiring diagram 1 – Main diagram Positive feeds Chassis connections Figure 1

Wiring diagram 1 – Main diagram Positive feeds Chassis connections

Wiring diagram 1 – Main diagram Positive feeds Chassis connections1 Figure 1

Wiring diagram 1 – Main diagram Positive feeds Chassis connections1

Wiring diagram 2 – Positive feed Chassis connection I-ECU E-ECU Figure 1

Wiring diagram 2 – Positive feed Chassis connection I-ECU E-ECU

Wiring diagram 2 – Positive feed Chassis connection I-ECU E-ECU1 Figure 1

Wiring diagram 2 – Positive feed Chassis connection I-ECU E-ECU1

Wiring diagram 3 – Engine Figure 1

Wiring diagram 3 – Engine

Wiring diagram 3 – Engine1 Figure 1

Wiring diagram 3 – Engine1

Wiring diagram 4 – D7 Engine ECU

Wiring diagram 4 – D7 Engine ECU1 Figure 1

Wiring diagram 4 – D7 Engine ECU1

Wiring diagram 5 – D10 Engine ECU

Wiring diagram 5 – D10 Engine ECU1 Figure 1

Wiring diagram 5 – D10 Engine ECU1

Wiring diagram 6 – D7, D10 Engine ECU Figure 1

Wiring diagram 6 – D7, D10 Engine ECU

Wiring diagram 6 – D7, D10 Engine ECU1 Figure 1

Wiring diagram 6 – D7, D10 Engine ECU1

Wiring diagram 7 – Accelerator pedal Fuel level Figure 1

Wiring diagram 7 – Accelerator pedal Fuel level

Wiring diagram 7 – Accelerator pedal Fuel level1 Figure 1

Wiring diagram 7 – Accelerator pedal Fuel level1 Figure 2

Wiring diagram 7 – Accelerator pedal Fuel level1

Wiring diagram 8 – Fan ECU Figure 1

Wiring diagram 8 – Fan ECU Figure 2

Wiring diagram 8 – Fan ECU

Wiring diagram 8 – Fan ECU1 Figure 1

Wiring diagram 8 – Fan ECU1

Wiring diagram 9 – Headlights Turn signals Horn Figure 1

Wiring diagram 9 – Headlights Turn signals Horn Figure 2

Wiring diagram 9 – Headlights Turn signals Horn

Wiring diagram 9 – Headlights Turn signals Horn1 Figure 1

Wiring diagram 9 – Headlights Turn signals Horn1 Figure 2

Wiring diagram 9 – Headlights Turn signals Horn1 Figure 3

Wiring diagram 9 – Headlights Turn signals Horn1

Wiring diagram 10 – EEC Headlights and flashers Figure 1

Wiring diagram 10 – EEC Headlights and flashers

Wiring diagram 10 – EEC Headlights and flashers1 Figure 1

Wiring diagram 10 – EEC Headlights and flashers1 Figure 2

Wiring diagram 10 – EEC Headlights and flashers1

Wiring diagram 11 – Work lights Figure 1

Wiring diagram 11 – Work lights

Wiring diagram 11 – Work lights1 Figure 1

Wiring diagram 11 – Work lights1 Figure 2

Wiring diagram 11 – Work lights1

Wiring diagram 12 – EEC Worklights

Wiring diagram 12 – EEC Worklights1 Figure 1

Wiring diagram 12 – EEC Worklights1 Figure 2

Wiring diagram 12 – EEC Worklights1

Wiring diagram 13 – Windshield wiper systems Figure 1

Wiring diagram 13 – Windshield wiper systems

Wiring diagram 13 – Windshield wiper systems1 Figure 1

Wiring diagram 13 – Windshield wiper systems1 Figure 2

Wiring diagram 13 – Windshield wiper systems1

Wiring diagram 14 – 25 amp 60 amp converter equalizer Figure 1

Wiring diagram 14 – 25 amp 60 amp converter equalizer

Wiring diagram 14 – Rotating beacons Differential lock MBCS Articulation sensor Figure 1

Wiring diagram 14 – Rotating beacons Differential lock MBCS Articulation sensor Figure 2

Wiring diagram 14 – Rotating beacons Differential lock MBCS Articulation sensor

Wiring diagram 15 – Rotating beacons differential lock MBCS Figure 1

Wiring diagram 15 – Rotating beacons differential lock MBCS

Wiring diagram 15 – Transmission ECU Figure 1

Wiring diagram 15 – Transmission ECU Figure 2

Wiring diagram 15 – Transmission ECU Figure 3

Wiring diagram 15 – Transmission ECU

Wiring diagram 16 – AWD ECU

Wiring diagram 16 – AWD ECU1 Figure 1

Wiring diagram 16 – AWD ECU1 Figure 2

Wiring diagram 16 – Transmission ECU Figure 1

Wiring diagram 16 – Transmission ECU Figure 2

Wiring diagram 16 – Transmission ECU

Wiring diagram 17 – AWD ECU Figure 1

Wiring diagram 17 – AWD ECU

Wiring diagram 17 – AWD ECU1 Figure 1

Wiring diagram 17 – AWD ECU1 Figure 2

Wiring diagram 17 – AWD ECU1 Figure 3

Wiring diagram 17 – AWD ECU1

Wiring diagram 18 – AWD ECU Figure 1

Wiring diagram 18 – AWD ECU Figure 2

Wiring diagram 18 – AWD ECU

Wiring diagram 18 – Sensors Figure 1

Wiring diagram 18 – Sensors Figure 2

Wiring diagram 18 – Sensors

Wiring diagram 19 – Brake circuit, lights Figure 1

Wiring diagram 19 – Brake circuit, lights Figure 2

Wiring diagram 19 – Brake circuit, lights

Wiring diagram 19 – Sensors Figure 1

Wiring diagram 19 – Sensors

Wiring diagram 20 – Brake circuit, lights Figure 1

Wiring diagram 20 – Brake circuit, lights

Wiring diagram 20 – Secondary steering Figure 1

Wiring diagram 20 – Secondary steering Figure 2

Wiring diagram 20 – Secondary steering

Wiring diagram 21 – Climate control unit Figure 1

Wiring diagram 21 – Climate control unit Figure 2

Wiring diagram 21 – Climate control unit Figure 3

Wiring diagram 21 – Climate control unit

Wiring diagram 21 – Secondary steering Figure 1

Wiring diagram 21 – Secondary steering

Wiring diagram 22 – Climate control unit Figure 1

Wiring diagram 22 – Climate control unit Figure 2

Wiring diagram 22 – Climate control unit

Wiring diagram 22 – Front and rear defroster fans Figure 1

Wiring diagram 22 – Front and rear defroster fans Figure 2

Wiring diagram 22 – Front and rear defroster fans

Wiring diagram 23 – Front defroster fans Figure 1

Wiring diagram 23 – Front defroster fans

Wiring diagram 23 – Radio Heated mirrors Figure 1

Wiring diagram 23 – Radio Heated mirrors Figure 2

Wiring diagram 23 – Radio Heated mirrors

Wiring diagram 24 – Blade float module Figure 1

Wiring diagram 24 – Blade float module Figure 2

Wiring diagram 24 – Blade float module

Wiring diagram 24 – Radio Dome light Heated mirrors Figure 1

Wiring diagram 24 – Radio Dome light Heated mirrors

Wiring diagram 25 – Blade float module Figure 1

Wiring diagram 25 – Blade float module

Wiring diagram 25 – Front float module Figure 1

Wiring diagram 25 – Front float module Figure 2

Wiring diagram 25 – Front float module

Wiring diagram 26 – Front float module Figure 1

Wiring diagram 26 – Front float module

Wiring diagram 26 – Tire pump Figure 1

Wiring diagram 26 – Tire pump Figure 2

Wiring diagram 26 – Tire pump

Wiring diagram 27 – Communication, E-ECU I-ECU Figure 1

Wiring diagram 27 – Communication, E-ECU I-ECU Figure 2

Wiring diagram 27 – Communication, E-ECU I-ECU

Wiring diagram 27 – Rear float module

Wiring diagram 28 – Keyboard Figure 1

Wiring diagram 28 – Keyboard Figure 2

Wiring diagram 28 – Keyboard

Wiring diagram 28 – Tire pump Power outlet Figure 1

Wiring diagram 28 – Tire pump Power outlet

Wiring diagram 29 – Communication, E-ECU I-ECU Figure 1

Wiring diagram 29 – Communication, E-ECU I-ECU

Wiring diagram 30 – Keyboard Figure 1

Wiring diagram 30 – Keyboard

Installation Instruction

- D7 Exhaust flex pipe kit, installing new

Fuel level sender kit, installing new

Installation Instruction Foreword for PDF, Road Machinery

Lower DuramideTM slide tube and bearing kit,

Radio antenna kit, installing new

Secondary steering pump and motor kit,

Repair

- Accumulator -Charging

Accumulator precharge adjustment chart

Accumulator precharge pressure, checking

Adjustment checks

Air conditioner service

Air Conditioning System Repairs

Air conditioning system

All Wheel Drive Operational Checks

All Wheel Drive Pump and Motor Priming Procedure

Articulation Hinge – Assembly

Articulation Hinge – Disassembly

Articulation hinge Figure 1

Articulation hinge

AWD error codes and troubleshooting

AWD test procedure and test port locations

Axle disassembly and assembly – G780B

Bearing Support Housing Installation

Blade lift arm, installing

Blade lift arm, removing

Blade lift cylinder, installing

Blade lift cylinder, removing

Blade lift stirrup, installing

Blade lift stirrup, removing

Brake Housing Pre – Assembly

Brake Master Cylinder and Power Booster – Installation

Brake Master Cylinder and Power Booster – Removal

Brake master cylinder, assembling

Brake master cylinder, disassembling

Circle adjustment

Circle and Drawbar – Assembly and Installation

Circle and Drawbar – Assembly and Installation1

Circle and Drawbar – Removal and Disassembly

Circle and Drawbar – Removal and Disassembly1

Circle Setup and Timing Figure 1

Circle Setup and Timing

Circle Timing

Circle turn mechanism, assembly

Circle turn mechanism, disassembly

Circle Turn Valve Overhaul Procedure

Circle turn valve, assembly

Circle turn valve, disassembly

Circle turn valve, installing

Circle turn valve, removing

Cleaning and inspection

Cleanliness, brake and hydraulic systems

Clutch assembly, installing

Clutch assembly, removing

Clutch Housing – Removal

Clutch Housing Installation

Clutch Slave Cylinder and Pedal Free Play Adjustment

Clutch Slave Cylinder and Pedal Free Play Adjustment1

Components Figure 1

Components

Components1

Compression test

Control Levers – Assembly

Control Levers – Cleaning and Inspection

Control Levers – Disassembly

Crankshaft, replacing rear oil seal

Cylinder head – D7D, description

Data link port

Drag link, installing

Drag link, removing

Drawbar ball stud, assembly

Drawbar ball stud, disassembly

Electric motor pump troubleshooting

Electric welding

Electrical component list

Electrical distribution box fuses, relays Figure 1

Electrical distribution box fuses, relays

Engine, removing

Engine, removing1

Error codes

Final Drive Assembly – Installation

Final Drive Assembly – Installation1

Final Drive Assembly – Removal

Final Drive Assembly – Removal1

Front axle frame, installing

Front axle frame, removing

Front Axle Pivot Pin Bearings – Disassembly

G700B Special tools

G710B to G746B circle and drawbar

G780B circle and drawbar

General

General1

Ground stud – locations

HVAC routine maintenance

HVAC system components

Hydraulic Cylinder – Assembly

Hydraulic Cylinder – Disassembly

Hydraulic Cylinder Overhaul Procedure

Hydraulic oil cleanliness

Hydraulic Oil Filler Cap – Prevention of Contaminants

Hydraulic oil return filter, replacing

Hydraulic swivel joint, assembly

Hydraulic swivel joint, disassembly

Hydraulic swivel joint, installing

Hydraulic swivel joint, removing

Hydraulic system troubleshooting guide

Hydraulic system troubleshooting

Hydraulic system, bleeding air

Injectors, replacing all

King Pin Bearings and Spindle Thrust Bearing – Assembly

King Pin Bearings and Spindle Thrust Bearing – Disassembly

Knuckle, installing

Knuckle, removing

Locking Strut – Troubleshooting

LS (load sense) Differential Pressure – Checking

LS (load sense) pressure, checking

Main Control Valve – Assembly

Main Control Valve – Disassembly

Main Control Valve Bleeding Procedure

Main control valve overhaul procedure

Main control valve troubleshooting

Main control valve, installation

Main control valve, removal

Main hydraulic pump troubleshooting guide

Mouldboard, shimming

Mouldboard, shimming1

Non-maintenance batteries, testing

Oil Disc Brake – Cleaning and Inspection

Oil disc brake assembly, removing

Oil disc brake, installing

Oil Disc Brakes – Bench Adjustment

Oil disc brakes , assembling

Oil disc brakes, disassembling

Parking Brake – Assembly

Parking Brake – Disassembly Figure 1

Parking Brake – Disassembly

Parking Brake – Installation

Parking Brake – Pre – Assembly

Parking brake assembly, removing

Parking brake overhaul procedure Figure 1

Parking brake overhaul procedure

Parking brake troubleshooting

Parking brake, adjusting

Parking brake, manually releasing

Pedestal Locking Strut – Setup

Pinion wear

Pivot Block – Assembly and Installation

Pivot Block Adjustments

Pivot block, removing and disassembling

Power booster, assembling

Power booster, disassembling

Preparation and Wheel Removal

Preventive maintenance

Product identification plates

Removing corrosion protective coating

Secondary steering system components

Secondary steering troubleshooting

Spindle – Assembly and Installation

Spindle – Removal and Disassembly

Steering axle – Assembly

Steering axle – Disassembly

Steering Column – Cleaning and Inspection

Steering column, assembling

Steering column, disassembling

Steering Control Unit – Assembly

Steering Control Unit – Bleeding Procedure

Steering Control Unit – Disassembly

Steering control unit overhaul procedure

Steering control unit troubleshooting

Steering control unit, installing

Steering control unit, removing

Steering Cylinder – Installation

Steering Cylinder – Removal

Steering system troubleshooting guide

Tandem assembly Figure 1

Tandem assembly

Tandem axle oil seal installation Figure 1

Tandem axle oil seal installation

Tandem Axle Seal – Installation

Tandem, removing

Tandem, removing1

Test procedures

Test procedures1

Tie bar, installing

Tie bar, removing

Tire troubleshooting guide

Toe – in, adjustment

Toe – in, adjustment1

Transmission components Figure 1

Transmission components

Transmission troubleshooting Figure 1

Transmission troubleshooting Figure 2

Transmission troubleshooting Figure 3

Transmission troubleshooting

Transmission, installing

Transmission, removing

Troubleshooting guide Low pressure gauge shown on left; high pressure gauge shown on right.

Troubleshooting guide

Valve Section – Assembly

Valve Section – Disassembly

Valves, adjusting

Valves, adjusting1

Wheel – Installation

Wheel Bearing – Cleaning and Inspection

Wheel Bearings – Assembly

Wheel Bearings – Disassembly

Wheel Hub – Installation

Wheel Hub – Removal

Wheel Lean Cylinder – Installation

Wheel Lean Cylinder – Removal

Safety

- CE marking and declaration of conformity

Check list after fire or heat exposure

Dimensions

Environment

Explosion hazard

Fire prevention measures

Health hazards with paint, plastics and rubber

Safety concerns everybody!

Safety concerns everybody!1

Safety when handling oil and fuel

Safety when handling the machine

Safety when handling tyres

Safety when lifting and supporting the machine

Safety when working on hydraulic systems

Safety when working on the electrical system

Safety when working with air-conditioning refrigerant

Safety when working with batteries

Service positions Figure 1

Service positions

Service Bulletins

- 100 Amp Alternator Kit

AC Condenser Wire

Accessory Mounting Bracket for the Roll Over Protective Structure (ROPS)

Accumulator Maintenance and Pressure Verification

Air filter restriction sensor

Alternator Pulley

Alternator Shields

Batteries

Brake piston back-up rings

CareTrack, new software version 2008w6

Charge Air Sensor Relocation

Circle Filler Plate

Circle Turn and Moldboard Slide Circuit Performance Improvement

Cooling Fan Control Valve

Cooling System Flushing

D7 Charge Air Hose

D-7 Engine Ground Cable

D7 Exhaust Flex Pipe Cracking

Defroster Fan

Diagnosing Oil Transfer Between the Engine and Transmission

Differential Lock Mechanism

Engine Door Bracket

Engine oil in the cooling system, coolant in the engine oil system and external oil leakage

Engine Protection

Filter Fitting for Load Sense Relief Valve

Fuel filter and water separator replacement interval change

Fuel Gauge Diagnosis

Fuel injector orientation in the D7D engine

Fuel sampling, method

G700, G700B Circle Tooth Template

G700B Cold Weather Starting Aids

G700B Ripper Cross Tube

G700B Snow Wing Board Installation

G700B Snow Wing Swivel

G700B Transmission Break-out Harness

Hydraulic Cooling Fan Operation & Diagnosis

Hydraulic Fan Failure

Hydraulic oil cleanliness

Hydraulic oil dye

Hydraulic Oil Filler Cap

Hydraulic system troubleshooting

I-ECU Software

Improved Lower Duramide™ Slide Bearing

Information On the A and L Transmission Coil Polarity

Lap Seat Belts

Leakage at engine oil pump gasket

Low Effort Brake Linkage for G700B Model Graders

Main Hydraulic Pump – Compensator Valve

Main hydraulic pump driveshaft coupling

New alternator

New rear frame guard

New ripper attachment for G700B graders

New starter switch

New TechTool VCADS Pro interface

New Wheel Rims

Oil Analysis

Parts & Service Training Material

Pedestal travel limiting spacer

Portable refillable O-ring kits

Product Update

Radio Antenna

Recirculation Vents – Description and Operation

Recommendations for Oil Sampling Intervals

Reporting of product misuse & near-miss report

Reports

Return Line Hydraulic Filter

Secondary Steering Pump and Motor

Severe Service Cab Mounts

Special tools

Steering Valve and Circuit

Tandem Bolt Torque Maintenance

Tandem Sprocket

Thermostat, replacing

Transmission Mounting Brackets

Transmission Solenoid Nut

Unauthorized modifications of Roll Over Protective Structure (ROPS)

UV Dye Added to Air Conditioning Receiver Dryer

Volvo Product incident accident report & Interview Form

Winter Air Intake Shields

Special Tools, Misc

- GRD G700B LabourTimeGuide

RM Compaction ABG Time Guide Old

RM Compaction Time guide old version

RM Paving Systems ABG Time Guide Old

Special Tools Recommendations

Time Guide Currrent generation

Time Guide Old generation

Time Guide Previous generation

Specifications

- Capacities

Cartridge

Cartridge1

Coolant

Critical mounting torques Figure 1

Critical mounting torques Figure 2

Critical mounting torques Figure 3

Critical mounting torques

Dimensions Figure 1

Dimensions

Endcap capscrews

Front axle pivot (G710B to G746B)

Front axle toe-in

Front axle toe-in1

Fuel system

General description – Wheels Figure 1

General description – Wheels Figure 2

General description – Wheels

General

Grease

Hydraulic cylinder specifications Figure 1

Hydraulic cylinder specifications

Injection pump – D10B, specifications

Injectors – D10B, specification

Intercooler D10B, specifications

Machine weights

Main control valve spool flow rates

Recommended lubricants

Relief setting

Secondary steering pressure switch

Section 2 Engine

Section 3 Electrical system

Section 4 Power transmission

Section 5 Brakes

Section 6 Steering

Section 9 Hydraulic system

Specifications – A-frame

Specifications – front mounted scarifier

Specifications – hydraulic snow wing

Specifications – mid mount scarifier

Specifications – one way plow

Specifications – push block

Specifications – ripper

Specifications – utility dozer blade

Specifications – V-plow

Specifications – windrow eliminator

Specifications, All Weel Drive system

Specifications, clutch master cylinder and booster circuit

Specifications, D7D – capacities

Specifications, D7D – general

Specifications, D7D – tightening torques

Specifications, D7D – weight

Specifications, D7D

Specifications, D10B – capacities

Specifications, D10B – general

Specifications, D10B – tightening torques

Specifications, D10B – weight

Specifications, engine clutch

Specifications, G780B – DR final drive

Specifications, SR final drive

Specifications, tandems

Specifications

Specifications1

Specifications2

Specifications3

Specifications4

Specifications5

Specifications6

Specifications7

Specifications8

Specifications9

Specifications10

Specifications11

Specifications12

Specifications13

Specifications14

Specifications15 Figure 1

Specifications15

Specifications16 Figure 1

Specifications16

Specifications17

Specifications18

Specifications19

Specifications20

Specifications21

Specifications22

Standard torque guide

Tightening torques

Tightening torques1

Tightening torques2

Torque Value for Adapter

Valve mechanism – D10B, specifications

Wheel rim bolt torque

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution