- No products in the cart.

Volvo ECR38 Excavator Service Repair Manual PDF

Size: 56.98 MB

Language: English

Make: Volvo

Machine: Excavator

Document: Service Repair Manual, Electrical Diagram, Hydraulic Diagram

Model: Volvo ECR38

US $50

Brands:

Volvo

Description

Volvo ECR38 Excavator Service Repair Manual PDF

Size: 56.98 MB

Language: English

Make: Volvo

Machine: Excavator

Document: Service Repair Manual, Electrical Diagram, Hydraulic Diagram

Model: Volvo ECR38

Page: 4008 Pages

Detail Contents:

1.ECR28 ECR38

Descriptions

- Alternator, description

Antitheft device, first activation of a new A-ECU

Automatic kick-down

Battery, description

Cab, description

Cable and component marking explanations

Camshaft, description

CareTrack W-ECU, description

Components list electr

Counterweight, description

Crankshaft, description 1

Crankshaft, description

Cylinder block, description

Cylinder head, description

Description, general

Electrical symbols and designation

Engine, description 1

Engine, description

Exploded view, cylinder block

Exploded view, cylinder head

Fuel filter, description

Fuel injection nozzle

Fuel injection pump, description

Fuel pump, description

Fuel system, description

Fuel tank, description

Fuel, recommendation

Fuse box, description

Gear motor, exploded view

Gear train and camshaft, description

General notes to be observe when working on power transmission assemblies

Hydraulic components, storage and transport

Hydraulic cylinders, dieseling

Hydraulic oil cooler, description

Hydraulic oil, description

Hydraulic oil, storage and handling

Hydraulic pump, description

Hydraulic tank, description

Infrared Thermometer

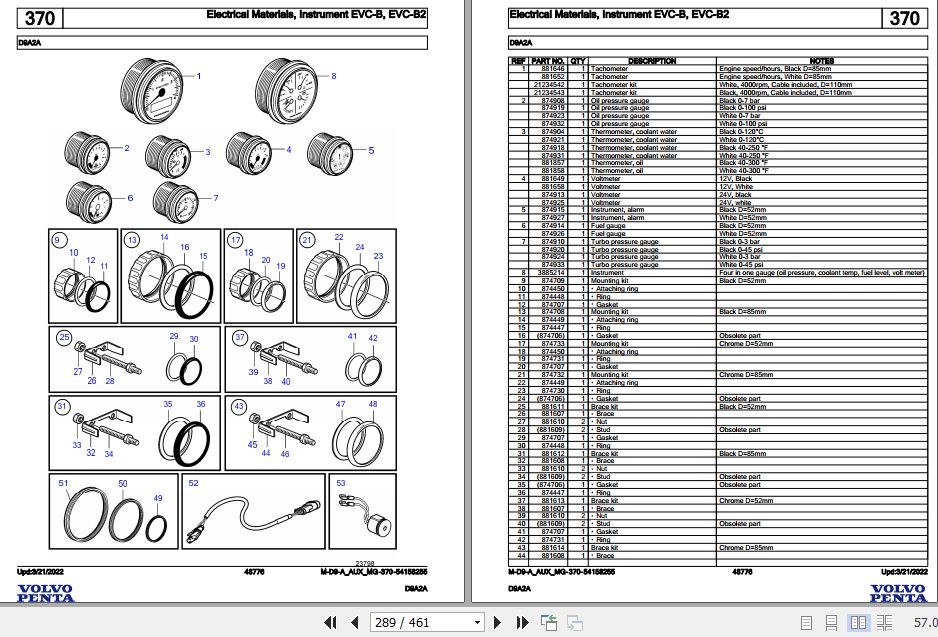

Instrument panel, description

Instrument panel, electrical circuit

Instrument panel, operation

Location of components

Lubricants, specifications

Lubricating system, description

Main control valve, description

Maintenance standards

Oil pump, description

Option anti-theft, instruction

Pistons, description

Product plate, description

Return line filter – description and operation

Service and maintenance

Shuttle valve, swing brake

Slew motor, break release valve

Slew motor, description 1

Slew motor, description

Starter motor, description

Starting engine with booster cables

Swivel joint, description

Tightening torque

Timing gear, description 1

Timing gear, description

Towing, measures

Transporting and lifting the machine

Travel motor, description

Travel motor, exploded view

Troubleshooting chart engine

Undercarriage, description

Valve cover, description and operation

Valve mechanism, description

Diagrams

- Hydraulic circuit (EU)

Hydraulic circuit (US)

Hydraulic circuit, accessories

Hydraulic circuit, boom

Hydraulic circuit, bucket

Hydraulic circuit, dipper arm

Hydraulic circuit, dozer blade

Hydraulic circuit, slewing gear and offset

Hydraulic circuit, travel motors

Hydraulic diagram 1

Hydraulic diagram 2

Hydraulic diagram 3

Hydraulic diagram 4

Hydraulic diagram 5

Hydraulic diagram 6

Hydraulic diagram 7

Hydraulic diagram 8

Hydraulic diagram 9

Hydraulic diagram 10

Hydraulic diagram, component list 2

Hydraulic diagram, component list 3

Hydraulic diagram, component list 4

Hydraulic diagram, component list 5

Hydraulic diagram, component list 6

Hydraulic diagram, component list 7

Hydraulic diagram, component list 8

Hydraulic diagram, component list 9

Hydraulic diagram, component list 10

Hydraulic diagram, component list

Hydraulic diagram, control pattern selector valve

Hydraulic diagram, swing system

Wiring diagram 1

Wiring diagram 2

Wiring diagram 3

Wiring diagram 4

Wiring diagram 5

Wiring diagram 6

Wiring diagram 7

Wiring diagram 8

Wiring diagram 9

Wiring diagram, cab and accessories

Wiring diagram, electronic system

Wiring diagram, engine part

Wiring diagram, general 1

Wiring diagram, general 2

Wiring diagram, hydraulic system

Wiring diagram, safety and service

Wiring diagram, working lights

Repair

- Adjusting operation

Adjusting the Track Tension

Adjustment of secondary valves

Air cleaner, description

Air cleaner, installing

Air cleaner, removing

Alternator, inspection

Alternator, installing

Alternator, removing

Assembling the crawler track

Assembling the guide sprocket

Assembling the rubber track

Assembling the superstructure

Assembling the top roller

Assembling the track roller

Assembling the travel motor

Auto idling device, description

Automatic idling device, installing

Automatic idling device, removing

Batteries, replacing

Battery condition, check

Bucket cylinder, installation

Bucket cylinder, removal

Cab door, changing door catch

Cab, installing

Cab, removing

Checking the hydraulic oil level 1

Checking the hydraulic oil level

Cleaning of the machine

Cleaning the oil cooler

Cold start device, description

Compression pressure inspection

Coolant pump, installing

Coolant pump, removing

Coolant, changing 1

Coolant, changing

Cooling system, description

Cooling system, disassembly assembly

Cooling system, flushing

Cooling system, maintenance

Counterweight, fitting

Counterweight, removing

Cylinder block, disassembly and assembly

Cylinder block, parts inspection and measurement

Cylinder head, disassembly assembly

Cylinder head, parts inspection and measurement

Cylinder speed

Dimensions

Door, replacing

Electronic system troubleshooting guide 2

Electronic system troubleshooting guide

Engine hood, installing

Engine hood, removing

Engine mounting

Engine mounts, removing

Engine mounts, replacing

Engine, air cleaner maintenance 1

Engine, air cleaner maintenance

Engine, changing oil and filter

Engine, installing

Engine, removing

Exhaust system, description

Fan belt and or alternator belt, checking and adjusting tension 1

Fan belt and or alternator belt, checking and adjusting tension

Fan belt and or alternator belt, replacing

FR pressure control valve, checking and adjusting

Fuel filter water separator, description

Fuel filter, replacing

Fuel injection pump, disassembly and assembly

Fuel level, checking

Fuel line, water separator, check and drain

Fuel line, water separator, check and drain1

Fuel lines, description

Fuel pump, installing

Fuel pump, removing

Fuel tank, installing

Fuel tank, removing

Gear train and camshaft, disassembly and assembly

Gear train and camshaft, parts inspection and measurement

Heater core, replacing

Hose rupture valve, installing new

Hydraulic oil cooler, installing

Hydraulic oil cooler, removing

Hydraulic oil filter, replacing

Hydraulic oil tank, changing oil

Hydraulic oil tank, installing

Hydraulic oil tank, removing

Hydraulic pump, replacing

Hydraulic swivel joint, installing

Hydraulic swivel joint, removing

Idling speed, checking and adjusting

Injectors, description

Instrument console, installing

Instrument console, removing

Instrument console, removing1

Instrument control unit I-ECU, description

Intake and exhaust system, description

LS pressure relief valve, checking and adjusting

Lubrication system, disassembly and assembly

Lubrication system, parts inspection and measurement

Main control valve, installation

Main control valve, removal

Measuring condition

Operator’s seat, installing

Operator’s seat, removing

Others, standard tightening torque

Paint and Finish

Periodic inspection and maintenance procedure

Periodic maintenance chart

Periodic maintenance

Pilot pressure, checking and adjusting

Protecting screen, installing new

Radiator, installing

Radiator, removing

Relays and fuses in engine compartment 1

Relays and fuses in engine compartment

Removing the crawler tracks

Removing the guide sprocket 1

Removing the guide sprocket

Removing the rubber track

Removing the superstructure

Removing the top roller

Removing the track roller

Removing the travel motor

Seat safety belt, replacing

Service points

Service position 2

Service position 3

Service positions

Silencer, installing

Silencer, removing

Sprocket, measurement of wear

Stand-by pressure

Starter motor, installing

Starter motor, removing

Swing motor, installing 1

Swing motor, installing

Swing motor, removing

Swing motor, replacing counterbalance valve

Tests and adjustments of the power control

Thermostat, replacing

Track tension, adjusting

Track tension, checking

Travel gear, dismantling

Travel gear, mounting

Travel Speed

V-ECU, replacing

Vehicle control unit V-ECU, description

Service Bulletins

- Adjustable X1 flow control

Boom

Capilarity leakage at the hose crimpings

Cylinder, improvement

Engine Tier 3 introduction

Fuel sampling, method

Internal leakage dozer blade, tolerance

Left console support, improvements

Main control valve leakage

Maintenance of Stored Machines

Muffler, modification

New coolant

New dashboard

New engine hood hinges

New hydraulic pump pressure hose

New product ECR28 – ECR38, Short-Radius

New slew motor brake kit

New starter switch

Option anti-theft, instruction

Pivot play tolerance and instruction

Pump companion

Reporting of product misuse & near-miss report

roduct improvements

Rotating beacon improvement

Slew motor improvement

Top roller, installation torque

Special tool catalog

- General

Index

Hooks

1. Enviroment and Safety equipment

2. Measuring equipment

3. Tightening and Loosening tools

4. Lifting equipment

5. Pullers and Pressing equipment

6. Drifts

7. Guide pins and Guide sleeves

8. Pliers

9. Fixtures

10. Tech Tool

11. Spare parts

Specifications

- Alternator, specifications

Battery, specification

Bottom track roller, tightening torque

Bucket, specifications

Cab, specifications

Capacities

Conversion tables

Cooling system, specifications

Drive gear, tightening torque

Electrical system, specifications

Engine, specifications

Frame, technical data

Fuel injection pump, specifications

Fuel system, specifications

Fuel, lubricant and filling capacities

Fuse box, specifications

Hammer, specification

Hydraulic cylinder specifications

Hydraulic system, specifications

Hydraulic tank, specifications’

Instrument panel, specifications

Slew motor, specifications

Slewing ring, tightening torques

Starter motor, specifications

Technical data

Top track roller, tightening torque

Track motor, specifications

VOLVO standard tightening torques

Weights

Time Guide Current generation

Time Guide Old generation

Time Guide Previous generation

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution