- No products in the cart.

Volvo EC55C Excavator Service Repair Manual PDF

Size: 175.25 MB

Language: English

Make: Volvo

Machine: Excavator

Document: Service Repair Manual, Electrical Diagram, Hydraulic Diagram

Model: Volvo EC55C

US $50

Brands:

Volvo

Description

Volvo EC55C Excavator Service Repair Manual PDF

Size: 175.25 MB

Language: English

Make: Volvo

Machine: Excavator

Document: Service Repair Manual, Electrical Diagram, Hydraulic Diagram

Model: Volvo EC55C

Page: 5425 Pages

Detail Contents:

1 Volvo EC55C

Description

- Actuator, foot face driver

Air cleaner, description

Alternator, description1

Alternator, description2

Auto Idle

Auxiliary start

Battery disconnector switch, description1

Battery disconnector switch, description2

Battery, description

Bearings

Boom lifting cylinder, description

Boom offset

Bottom roller, description

Bucket cylinder, description

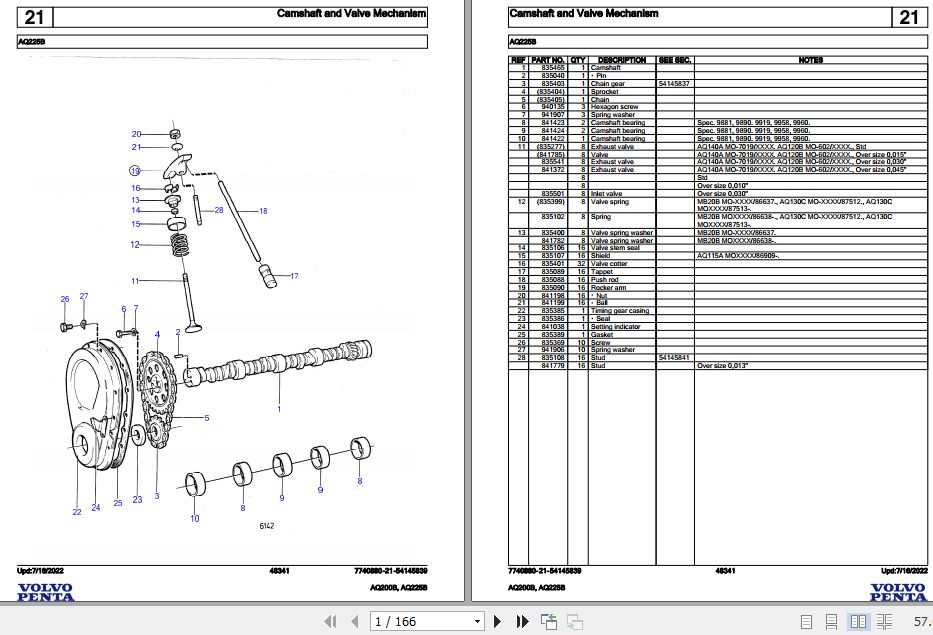

Camshaft, description

Center passage, description1

Center passage, description2

Center passage, troubleshooting

Checking and Adjusting procedure

Cleaning prior to repair

Clogged engine air filter

Coil resistor

Cold start device, description1

Cold start device, description2

Communication with data buses

Compressor

Condenser

Connectors, overview1

Connectors, overview2

Control pattern selector valve, description

Control pattern selector valve, ports

Control valve, troubleshooting

Cooling system, description1

Cooling system, description2

Counterweight, description

Crankshaft, description

Cylinder block, description

Cylinder head, description

Cylinder, troubleshooting

Daily hours

Description, general

Digging unit, description

Dipper arm cylinder, description

Dozer blade float, description

Dozer blade, description

Electric horn, description1

Electric horn, description2

Electrical distribution box1

Electrical distribution box2

Electrical distribution box3

Electrical system, description

Electrical system, special instructions for servicing electronic components

Electrical system, special instructions for servicing, action when working on machine

Electrical system, special instructions for servicing, electrical components, alternator and charging regulator

Electrical system, special instructions for servicing, electrical components, batteries

Electrical system, special instructions for servicing, general

Electrical system

Electronic control system, description

Engine characteristic curve1

Engine characteristic curve2

Engine characteristic curve3

Engine control unit E-ECU, function description

Engine coolant temperature

Engine oil pressure

Engine speed control switch, description

Engine start

Engine stops

Engine system

Engine timing gear, description

Engine, description1

Engine, description2

Engine, identification

Engine, tightening torque

Evaporator

Examples, hydraulic system

Examples, power transmission

Exhaust Gas Recirculation (EGR), description

Exhaust system, description

Expansion valve

Faulttracing

Frame and track unit, description

Fuel filler pump, description

Fuel injection pump governor, description

Fuel injection pump, description

Fuel lines, description

Fuel system, description1

Fuel system, description2

Fuel tank, description

Fuel

Fuse, description

General notes when working on hydraulic system

GPS control unit GPS-ECU, description

Hoses and tubes

Hour meter

Hydraulic components, description

Hydraulic control

Hydraulic diagram, ports

Hydraulic diagram, schematic

Hydraulic oil, description

Hydraulic pump coupling, description1

Hydraulic pump coupling, description2

Hydraulic system, position of main components

Hydraulic system

Hydraulic tank, description

Idler, description

Injectors, description

Inlet system, description

Instrument control unit I-ECU, function description

Instrument control unit I-ECU, specifications

Instrument panel, operation

Intermittent wiper and washer

Line rupture valve (arm), troubleshooting

Line rupture valve (boom arm), description

Line rupture valve (boom arm), hydraulic circuit

Line rupture valve (boom), troubleshooting

Lubricating system, description1

Lubricating system, description2

MA9109 Quickfit solenoid valve, description

Machine view

Main control valve, description

Main control valve, operation

Main relief valve, description

Maintenance standards1

Maintenance standards2

Menu tree1

Menu tree2

Overload warning device, operation

Overload warning

Pistons, description

Port relief valve, description

Power transmission, description

Precautions

Preheating, description

Pressure accumulator, description

Pressure adjustment and leaks checking

Pressure relief valve, troubleshooting

Pressure testing

Product plates

Proportional solenoid valve, description

Pump, description

Pump, troubleshooting

Quick attachment, description

Quickfit system, operation

Radiator, description

Radio with CD and MP3 player, description

Recommended lubricants

Refrigerant hoses

Relay, description1

Relay, description2

Remote control valve (Lever), description

Remote control valve (Lever), troubleshooting

Remote control valve (pedal), description

Remote control valve (pedal), troubleshooting

Replacement parts

Rotator pump, description

Rubber pads2

Rubber shoe pad usage

Rubber tracks1

Seat belt

Selection of track shoes

Service methods

Service mode1

Service mode2

Service positions

Service

Servo pump, description

Slew motor, precautions for installation

Slew motor, troubleshooting

Slew ring gear, description

Slow blow fuse, description

Software parameters, description

Solenoid valve, description

Special tools

Standard of the setting pressure

Start switch, description1

Start switch, description2

Starter motor, description

Starting engine with booster cables

Starting operation1

Starting operation2

Stop solenoid, description

Stop valve

Swing gearbox, description

Swing motor, description

Top roller, description

Track chain, description

Track gearbox, description1

Track gearbox, description2

Track gearbox, description3

Track gearbox, description4

Track gearbox, precautions for operation

Track gearbox, troubleshooting

Track motor, description1

Track motor, description2

Track motor, description3

Track motor, description4

Track motor, maintenance standard

Track motor, operating checks

Track motor, precaution for installation

Track motor, tools

Track motor, troubleshooting

Travel alarm, description1

Travel alarm, description2

Troubleshooting chart

Troubleshooting, diagnosing procedure

Troubleshooting

Undercarriage, description

V-ECU function, auto return to idle

V-ECU function, boom offset

V-ECU function, preheating

V-ECU function, quickfit

Vehicle control unit V-ECU, function description

Vehicle control unit V-ECU, specifications1

Vehicle control unit V-ECU, specifications2

Warranty inspection

Windscreen wiper, description

Wiper motor, description

Work lights and headlights, description

X1 Line, description

Diagrams

- Component designations

Component list Alternator, batteries, capacitors, electronic units, voltage outlet

Component list Control lights warning lights1

Component list Control lights warning lights2

Component list, Fuses1

Component list, Fuses2

Component list, Fuses3

Component list, Heating coils1

Component list, Heating coils2

Component list, Heating coils3

Component list, Lights

Component list, Miscellaneous1

Component list, Miscellaneous2

Component list, Miscellaneous3

Component list, Motors1

Component list, Motors2

Component list, Relays1

Component list, Relays2

Component list, Relays3

Component list, Sensors1

Component list, Sensors2

Component list, Sensors3

Component list, Solenoid valves1

Component list, Solenoid valves2

Component list, Switches1

Component list, Switches2

Component list, Switches3

Control system diagram1 Figure1

Control system diagram1

Control system diagram2 Figure1

Control system diagram2

Electrical circuit, air conditioner heater1

Electrical circuit, air conditioner heater2

Electrical symbols and designations

Explanation of wiring diagrams

Explanations to hydraulic diagram

Grounding points (frame connections)

Hydraulic diagram, standard Figure 1

Hydraulic diagram, standard Figure 2

Hydraulic diagram, standard

Hydraulic diagram, with option component1 Figure 1

Hydraulic diagram, with option components1 Figure 2

Hydraulic diagram, with option components1 Figure 3

Hydraulic diagram, with option components1

Hydraulic diagram, with option components2 Figure 1

Hydraulic diagram, with option components2 Figure 2

Hydraulic diagram, with option components2 Figure 3

Hydraulic diagram, with option components2

Wiring diagram SCH01-1

Wiring diagram SCH01-2

Wiring diagram SCH01-3

Wiring diagram SCH01-4

Wiring diagram SCH02-1

Wiring diagram SCH02-2

Wiring diagram SCH02-3

Wiring diagram SCH02-4

Wiring diagram SCH03-1

Wiring diagram SCH03-2

Wiring diagram SCH03-3

Wiring diagram SCH04-1

Wiring diagram SCH04-2

Wiring diagram SCH04-3

Wiring diagram SCH04-4

Wiring diagram SCH07-1

Wiring diagram SCH07-2

Wiring diagram SCH07-3

Wiring diagram SCH07-4

Wiring diagram SCH07-5

Wiring diagram SCH08-1

Wiring diagram SCH08-2

Wiring diagram SCH08-3

Wiring diagram SCH08-4

Wiring diagram SCH08-5

Wiring diagram SCH08-6

Wiring diagram SCH10-1

Wiring diagram SCH10-2

Wiring diagram SCH10-3

Wiring diagram SCH10-4

Wiring diagram SCH11-1

Wiring diagram SCH11-2

Wiring diagram SCH11-3

Wiring diagram SCH11-4

Wiring diagram SCH12-1

Wiring diagram SCH12-2

Wiring diagram SCH12-3

Wiring diagram SCH13-1

Wiring diagram SCH13-2

Wiring diagram SCH13-3

Wiring diagram SCH13-4

Wiring diagram SCH13-5

Wiring diagram SCH13-6

Wiring diagram SCH13-7

Wiring diagram SCH14-1

Wiring diagram SCH14-2

Wiring diagram SCH14-3

Wiring diagram SCH14-4

Wiring diagram SCH15-1

Wiring diagram SCH15-2

Wiring diagram SCH22

Wiring diagram SCH24

Wiring diagram SCH25-1

Wiring diagram SCH25-2

Wiring diagram SCH26

Wiring diagram1

Wiring diagram2

Wiring harnesses Figure 1

Wiring harnesses

Installation Instruction

- 1.6m Arm piping with gr manuovre

1.6m Arm piping with quick fit single

1.9m Arm piping with gr manuovre

1.9m arm piping with Quick fit-Single

1.9m arm piping with Quick fit-Single1

Boom piping with H-RUPT protection Arm cylinder

CareTrack, installing new

CareTrack, installing new1

Cassette_Domestic INT

Cassette_Europe

Cassette_NAFTA

CDP or MP3

Dozer blade, installing new

Dozer blade, installing new1

Extra work lamp- boom right hand

FOG + FOPS

FOPS

Hose rupture protection boom cyinder with O-L warning

Piping kit, X1 Double and offset piping

Piping kit, X1 Double for Fix

Piping kit, X1 Double piping for THUMB

Piping kit, X1 Single for Fix with A Decel

Piping kit, X1 Single for Fix

Piping kit, X3 Boom for Fix_PTO

Piping kit, X3 Boom for swing_PTO

Quick fit boom piping

Quick fit boom piping-Single

Quick fit dual piping on 1.6m arm

Quick fit dual piping on 1.9m arm

Quick fit piping on arm, installing new

Quick fit piping on base machine(Double)

Quick fit piping on base machine(Double)1

Quick fit piping on base machine(Single)

Quick fit, installing new

Radio, installing new

Rear extra lamp in cabin (beacon lamp and rear work lamp)

Rear view side mirror

Thumb, quick attachment, installing new

Thumb, standard bucket, installing new

Track assembly, installing new

Travel alarm, installing new

Travel alarm

Work light on cab, installing new

Work light on cab, installing new1

Work light on mono boom, installing new

Work light on mono boom, installing new1

X1 piping on 1.6m arm

X1 piping on 1.9m arm

X3 piping on 1.6m Arm

X3 piping on 1.9m Arm - Repair

- Air cleaner primary filter, change

Air cleaner primary filter, clean

Air cleaner secondary filter, change

Air cleaner, cleaning filter element

Air cleaner, primary filter replacing

Air cleaner, secondary filter replacing

Air conditioner main filter, change1

Air conditioner main filter, change2

Air conditioner main filter, clean1

Air conditioner main filter, clean2

Air conditioning unit, maintenance

Air conditioning unit, refrigerant check and recharging

Alternator, inspection

Alternator, replacing incl function check

Antenna, replacing

Batteries, replacing1

Batteries, replacing2

Battery condition, check

Battery, charging

Belts and belt tension, check, replace when needed.1

Belts and belt tension, check, replace when needed.2

Belts and belt tension, check, replace when needed.3

Boom cylinder, replacing

Boom, replacing

Bottom roller, measurement of wear

Bottom roller, replacing one

Bucket cylinder, replacing

Bushing general, replacing

Cab, installing1

Cab, installing2

Cab, removing1

Cab, removing2

Cab; door, covers, hinges, joints and locks, lubricate

Center passage hose (center passage – motor), replacing

Center passage hose (valve – center passage), replacing

Center passage, assembly

Center passage, disassembly

Center passage, maintenance standard

Center passage, tools

Check valve, replacing

Check valve, replacing1

Coasting left and right swing

Component locations1

Component locations2

Compressor, replacing incl draining and filling

Condenser, replacing incl draining and filling

Condition test and maintenance program

Connecting rod yoke, replacing

Control pattern selector valve, mode setting method

Control valve, replacing

Coolant level, check

Coolant, change

Coolant, changing

Coolant, checking anti-freeze resistance

Coolant, checking anti-freeze resistance1

Cooler and Heater assembly, installation

Cooler and Heater assembly, removal

Creeping of hydraulic cylinder

Cylinder speed1

Cylinder speed2

Cylinder speed3

Defroster actuator, replacing

Digging unit, maintenance standard

Dipper arm connecting rod, replacing

Dipper arm cylinder, replacing

Dipper arm, replacing

Door window, replacing

Dozer blade cylinder, replacing

E-ECU, MID 128, changing non-Programd ECU

E-ECU, MID 128, changing pre-Programd ECU

Engine control1

Engine control2

Engine control3

Engine EGR valve, cleaning

Engine hood, replacing

Engine mounting1

Engine mounting2

Engine oil and filter, changing1

Engine oil and filter, changing2

Engine oil filter, replacing

Engine oil level, checking

Engine oil pressure sensor, replacing

Engine radiator and hydraulic oil cooler, check (clean when necessary)

Engine temperature sensor, replacing

Engine, oil level, check1

Engine, oil level, check2

Evaporator, replacing incl draining and filling

Exhaust pipe, flexible tube, replacing

Expansion tank, replacing1

Expansion tank, replacing2

Expansion valve, replacing incl draining and filling

Fan belt and or alternator belt, checking and adjusting tension

Fan belt and or alternator belt, replacing

Fan belt and or alternator-, compressor belt, replacing all belts

Fan motor, replacing

Front idler, replacing one

Fuel filling pump, installing

Fuel filling pump, removing

Fuel filter extra (water separator element), check drain

Fuel filter, change

Fuel filters, replacing

Fuel injectors, inspect clean and test1

Fuel injectors, inspect clean and test2

Fuel level sender, replacing

Fuel tank sediment, drain

Heater core, replacing

Horn, replacing

Hydraulic oil level, check

Hydraulic oil return filter, replacing

Hydraulic oil servo filter, change

Hydraulic oil suction strainer, clean

Hydraulic oil tank, vacuum-pumping, connecting and disconnecting pump

Hydraulic oil, changing

Hydraulic pump (removed), changing shaft seal

Hydraulic pump, replacing

Hydraulic tank breather filter, clean

Idler, measurement of wear

I-ECU, MID 140, changing non-Programd ECU

I-ECU, MID 140, changing pre-Programd ECU

I-ECU, replacing

Intake actuator, replacing

Loose and loss of bolts, check

Lubrication oil pressure, checking with pressure gauge

Lubrication, see lubrication chart

Main control valve, assembly

Main control valve, disassembly

Main pressure relief valve, replacing

Main relief valve, adjusting

Main relief valve, assembly

Main relief valve, disassembly

Main switch, replacing

Maintenance service, daily

Maintenance service, every 50 hours

Maintenance service, every 250 hours

Maintenance service, every 500 hours

Maintenance service, every 1000 hours1

Maintenance service, every 1000 hours2

Maintenance service, every 2000 hours1

Maintenance service, every 2000 hours2

Maintenance service, every 4000 hours1

Maintenance service, every 4000 hours2

Maintenance service, every 6000 hours1

Maintenance service, every 6000 hours2

MATRIS, reading, export reading

Measuring condition

Measuring of swing bearing clearance

Mode (foot) actuator, replacing

Oil cooler, replacing

Oil cooler, replacing1

Oil level gauge, replacing

Operator’s seat, installing

Operator’s seat, removing

Pipe and hose (pump – valve), replacing

Port relief valve pressure, checking and adjusting

Port relief valve, assembly

Port relief valve, disassembly

Preheating coil, replacing1

Preheating coil, replacing2

Pre-heating relay, replacing

Pump gearbox coupling assembly, replacing

Pump suction hose and pipe, replacing

Pump, assembly

Pump, disassembly

Pump, maintenance standard

Pump, tools

Quickfit solenoid valve, replacing

Quickfit, installation

Quickfit, removal

Quickfit, removal1

Radiator hose upper, replacing

Radiator hoses lower, replacing1

Radiator hoses lower, replacing2

Radiator, replacing

Radio, replacing

Rear window, replacing

Remote control valve (Lever), maintenance standard

Remote control valve (lever), replacing

Remote control valve (pedal), assembly

Remote control valve (pedal), disassembly

Remote control valve (pedal), maintenance standard

Remote control valve (pedal), replacing

Rubber track, installing

Rubber track, removing

Rupture valve, replacing (boom cylinder)

Rupture valve, replacing (dipper arm cylinder)

Seat, replacing

Service history (included in the respective Operator’s manual), fill in.

Servo pressure, checking and adjusting

Servo pump, replacing

Side window, replacing

Silencer, replacing

Slew ring gear, installation

Slew ring gear, removal

Solenoid valve, disassembly and assembly

Solenoid valve, inspection

Solenoid valve, replacing

Speaker, replacing

Spring package, measurement of wear

Sprocket, measurement of wear

Sprocket, replacing one

Starter motor, replacing

Starter relay, replacing

Starter switch (engine start switch), replacing

Straight traveling performance

Superstructure, installation

Superstructure, removal

Swing bath grease, lubricate

Swing gearbox oil level, check

Swing gearbox, assembly

Swing gearbox, disassembly

Swing gearbox, maintenance standard

Swing gearbox, replacing

Swing motor gearbox, changing oil

Swing motor relief valve, replacing

Swing motor, assembly

Swing motor, disassembly

Swing motor, maintenance standard

Swing ring gear bearing, lubricate

Swing speed1

Swing speed2

Swing speed3

Test-run and check

The machine, check for external damages, cracks and wear damages

Thermostat, checking

Thermostat, replacing

Tools & equipment

Top roller, measurement of wear

Top roller, replacing one

Track chain assembly, installing

Track chain assembly, removing

Track chain, measurement of wear

Track gearbox oil level, check

Track gearbox, assembly

Track gearbox, disassembly

Track gearbox, maintenance standard

Track gearbox, replacing cover

Track guard, replacing one

Track links, replacing

Track motor gearbox, changing oil

Track motor, assembly

Track motor, disassembly

Track motor, measurement

Track recoil spring (tensioner) assembly, replacing

Track running speed1

Track running speed2

Track shoe bolts, check

Track shoe, replacing one

Track tension condition, check

Track tension cylinder, replacing

Track unit, replacing

Track, adjusting track sag

Track, adjusting track sag1

Travel alarm, replacing

Travel Speed1

Travel Speed2

Valve clearance, check adjust1

Valve clearance, check adjust2

Valve covers, fitting new gasket

Valves, adjusting

VCADS Pro, logged errors, read off

V-ECU, MID 187, changing non-Programd ECU

V-ECU, MID 187, changing pre-Programd ECU

V-ECU, replacing

Vent actuator, replacing

Warranty inspection 100 hours

Washer fluid level, check

Water valve, replacing

Windscreen flusher pump, replacing

Windscreen wiper front, replacing motor

Windscreen, replacing

Work lighting, replacing one head lamp assy - Safety

- Cautions during operation

CE-marking, EMC-directive

Checklist after a fire or heat exposure

Decontamination

Environmental handling for the future

Environmentally hazardous fluids

Environmentally safe handling

Fire prevention measures

General precautions

Health hazards with paint, plastics and rubber

Move and operate machine safely

Preparations for work

Safety concerns everybody!

Safety rules when servicing

Safety when handling oils and fuel

Safety when using lifting equipment

Safety when working with air conditioning refrigerant

Safety when working with batteries

Safety when working with hydraulic systems

Starting with booster batteries

Waste handling

Working in environmentally contaminated areas - Service Bulletins

- AC evaporator, improvement

Air conditioning adapter pipe

Air conditioning compressor mounting bolt

Air conditioning evaporator

Air conditioning switch

Air conditioning unit, compressor guard improvement

Alternator improvement

Arm cylinder leakage

Arm rest latch improvement

Attachment shims for clearance adjustment of pin joint

Auto idle relay change

Auto idle solenoid bracket improvement

Auto idle solenoid

Battery maintenance guideline for long term stock machines

Boom working lamp cable

Bottom roller improvement

Bucket cylinder hose improvement

Bucket cylinder hose leakage

Cab door latch

Cab front glass, leakage

Cab heater water valve bracket

Coolant leakage from timing gear case

Cylinder head gasket

Dipper arm welding

Dozer blade check valve

Dozer blade check valve1

Engine hood deformation

Engine hood deformation1

Engine hood latch change

Engine speed control switch

Expansion tank, improvement

Expansion tank, improvement1

Front window locking improvement

Fuel level indicator

Fuel sampling, method

Idler bracket

I-ECU moisture

Main control valve, holding valve

Main pump shaft seal

Maintenance of Stored Machines

New product

New product1

New product2

New software, V-ECU

New TechTool VCADS Pro interface

Offset boom cylinder drift

Portable refillable O-ring kits

Quick coupler improvement (X1 single acting)

Quick coupler leakage

Quickfit solenoid valve

Quickfit switch change

Quickfit switch malfunction

Reporting of product misuse & near-miss report

Rubber track improvement

Swing ring gear seal improvement

Track gearbox internal damage

Travel alarm

Travel speed down at low temperature

V-belt improvement

Volvo Product incident accident report & Interview Form

Washer pump improvement

Washer pump improvement1

Water separator improvement

Window wiper

X1 return hose leakage

X1 supply hose leakage - Special Tools, Misc

- 01 Time Guide Current generation

11 Time Guide Previous generation

21 Time Guide Old generation

35 GRD G700B LabourTimeGuide

40 RM Compaction Time guide

41 RM Compaction ABG Time Guide Old

42 RM Paving Systems ABG Time Guide Old

Special tool catalog

Special Tools Recommendations - Specifications

- Air conditioning unit, specifications1

Air conditioning unit, specifications2

Alternator, specifications1

Alternator, specifications2

Battery, specifications1

Battery, specifications2

Boom lifting cylinder, specifications

Boom slew cylinder, specifications

Boom, specifications

Bucket cylinder, specifications

Center passage, specifications

Check valve, specifications

Control valve, specifications

Cooling system, specifications1

Cooling system, specifications2

Counterweight, specifications

Dipper arm cylinder, specifications

Dipper arm, specifications

Dozer blade cylinder, specifications

Dozer blade, specifications

Electric horn, specifications

Electrical system, specifications

Engine, specifications1

Engine, specifications2

Engine, specifications3

Frame and track unit, specifications

Fuel filler pump, specifications

Fuel injection pump, specifications

Fuel system, specifications

Fuel tank, specifications

Grease

Hydraulic oil cooling system, specifications

Hydraulic pressure, specifications1

Hydraulic pressure, specifications2

Hydraulic pressure, specifications3

Hydraulic pressure, specifications4

Hydraulic pump, specifications

Hydraulic tank, specifications

Injectors, specification

Injectors, specification1

Instrument control unit I-ECU, specifications

Instrument control unit I-ECU, specifications1

Line rupture valve (boom arm), specifications

Lubrication system, specifications

Lubrication system, specifications1

MA9109 Quickfit solenoid valve, specifications1

MA9109 Quickfit solenoid valve, specifications2

Measurement conversion tables

Overload warning pressure switch, specifications

Preheating, specifications1

Preheating, specifications2

Pressure accumulator, specifications

Recommended hydraulic oil, specifications

Relay, specifications1

Relay, specifications2

Remote control valve (Lever), specifications

Remote control valve (pedal), specifications

Rotator pump, specifications

Servo pump, specifications

Solenoid valve for rotator1

Solenoid valve for rotator2

Solenoid valve, specifications1

Solenoid valve, specifications2

Specification, filling capacities

Specification, filling capacities1

Standard tightening torques

Start switch, specifications1

Start switch, specifications2

Starter motor, specifications1

Starter motor, specifications2

Swing gearbox, specifications

Swing motor, specifications

Swing ring gear, specifications

Tightening torque, specifications

Tightening torque, specifications1

Tightening torque, specifications2

Track gearbox, specifications1

Track gearbox, specifications2

Track gearbox, specifications3

Track motor, specifications1

Track motor, specifications2

Track motor, specifications3

Travel alarm, specifications1

Travel alarm, specifications2

Undercarriage, tightening torque

Valve system specifications

Wiper motor, specifications

Work lights and headlights, specifications - Other Products

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution