- No products in the cart.

Volvo EC210C N Excavator Service Repair Manual PDF

Size: 124.93 MB

Language: English

Make: Volvo

Machine: Excavator

Document: Service Repair Manual, Electrical Diagram, Hydraulic Diagram

Model: Volvo EC210C N

US $50

Brands:

Volvo

Description

Volvo EC210C N Excavator Service Repair Manual PDF

Size: 124.93 MB

Language: English

Make: Volvo

Machine: Excavator

Document: Service Repair Manual, Electrical Diagram, Hydraulic Diagram

Model: Volvo EC210C N

Page: 1558 Pages

Detail Contents:

EC210C N

Repair

- 2 stage port relief valve, adjustment

Accumulator, replacing

Adjustable boom valve, disassembly

Air cleaner primary filter, change

Air cleaner primary filter, clean

Air cleaner secondary filter, change

Air conditioner main filter, change

Air conditioner main filter, clean

Air conditioning unit, maintenance

Air mix door actuator, replacing

Alternator, replacing incl function checking

Antenna, replacing

Arm parallel conflux check valve, disassembly and assembly

Arm parallel conflux valve, disassembly and assembly

Arm regenerating valve, disassembly

Arrival Inspection, according to Inspection Program

Batteries, replacing

Battery condition, check

Battery, charging

Belts and belt tension, check, replace when needed.

Boom 2 conflux shut-off valve, disassembly

Boom and arm holding valve (Boom-1, Arm-1), disassembly

Boom back pressure check valve, disassembly

Boom cylinder, rupture valve, replacing

Boom, installing

Boom, removing

Boom, replacing

Bottom roller, assembly

Bottom roller, disassembly

Bottom roller, measurement of wear

Bottom roller, replacing one

Bottom roller, replacing seal

Breather, replacing

Bucket assembly, installing

Bucket assembly, removing

Bucket assembly, replacing

Bucket cylinder, installing

Bucket cylinder, removing

Bucket cylinder, repacking in machine

Bucket cylinder, replacing

Bucket flow control valve, disassembly

Bucket regenerating valve, disassembly

Cab elevating cylinder, replacing

Cab filter, replacing

Cab, installing

Cab, prefilter, clean

Cab, prefilter, replace

Cab, removing

Cab; door, covers, hinges, joints and locks, lubricate

Camshaft and flywheel signals, checking with VCADS Pro and oscilloscope

Carbon dioxide in fuel system, checking

Center bypass valve, disassembly and assembly

Center passage hose (center passage – motor), replacing

Center passage hose (valve – center passage), replacing

Center passage, assembly

Center passage, disassembly

Center passage, inspection and troubleshooting

Center passage, replacing seal kit

Center passage, replacing

Charge air cooler connection (hose, tube), replacing

Charge air cooler, replacing

Coasting left and right swing

Component locations

Compressor, replacing incl draining and filling

Condenser, replacing incl draining and filling

Connecting rod yoke, installing

Connecting rod yoke, removing

Connecting rod yoke, replacing

Control lockout lever switch, replacing

Control types for X1 and X3 operation

Coolant anti-freeze resistance, checking 2

Coolant anti-freeze resistance, checking

Coolant level, check

Coolant, change

Coolant, changing

Cooler and Heater assembly, replacing

Counterweight, installing 2

Counterweight, installing

Counterweight, removing

Creeping of hydraulic cylinder

Cylinder speed

Delivery Inspection, according to Inspection Program

Digging unit, maintenance

Dipper arm connecting rod, installing

Dipper arm connecting rod, removing

Dipper arm connecting rod, replacing

Dipper arm cylinder, installing

Dipper arm cylinder, removing

Dipper arm cylinder, repacking in machine

Dipper arm cylinder, replacing

Dipper arm cylinder, rupture valve, replacing

Dipper arm, installing

Dipper arm, removing

Dipper arm, replacing

Door window, replacing

Earth lead to battery, replacing

ECC (Electronic Climate Control), replacing

E-ECU MID 128 non-Programd, replacing 2

E-ECU MID 128 non-Programd, replacing

E-ECU MID 128 pre-Programd, replacing 2

E-ECU MID 128 pre-Programd, replacing

Engine hood, replacing

Engine mounting

Engine oil and filter, changing

Engine rotation speed sensor (camshaft), replacing

Engine speed control switch, inspection

Engine speed control switch, replacing

Engine wire harness, replacing

Engine, oil level, check

Engine, tightening torques

E-tools, NET 8940-00270 Replace tool for the swing ring gear

E-tools, NET 8940-00300 Swing ring gear guide pin

Evaporator, replacing incl draining and filling

Exhaust pipe flexible tube, replacing

Expansion tank, replacing

Expansion valve, replacing incl draining and filling

Fan belt and or alternator belt, replacing

Fan belt and or alternator-, compressor belt, replacing all belts

Fan motor, assembly 2

Fan motor, assembly

Fan motor, disassembly

Fan motor, replacing

Fan motor, tools

Fan pump, assembly 2

Fan pump, assembly

Fan pump, disassembly

Feed pump pressure, checking

Feed pump, replacing

Fire extinguisher, fault indication

Flow control valve, disassembly and assembly

Front idler, replacing one

Fuel control valve (FCV), replacing

Fuel filling pump, installing

Fuel filling pump, removing

Fuel filter extra (water separator element), check drain

Fuel filter extra, replacing

Fuel filter housing, replacing

Fuel filter, change

Fuel filter, checking

Fuel filters, replacing

Fuel pump, inspecting

Fuel rail pressure, checking

Fuel system, bleeding

Fuel tank air ventilation filter, change

Fuel tank sediment, drain

General, precautions

General, tools

Heater core, replacing

Horn, replacing

Hydraulic oil drain filter, change

Hydraulic oil level, check

Hydraulic oil return filter, replacing

Hydraulic oil servo filter, change

Hydraulic oil suction strainer, clean

Hydraulic oil tank breather filter, replacing

Hydraulic oil tank, vacuum-pumping, connecting and disconnecting pump

Hydraulic oil, changing

Hydraulic pump (removed), changing shaft seal

Hydraulic pump regulator, replacing

Hydraulic pump, maintenance standard, Specifications

Hydraulic quickfit, adjustment

Idler, assembly

Idler, disassembly

Idler, measurement of wear

I-ECU MID 140 pre-Programd, replacing 2

I-ECU MID 140 pre-Programd, replacing

Injector, replacing one

Instrument panel (left), replacing

Instrument panel (right), replacing

Intake actuator, replacing

Line rupture valve (arm), disassembly

Line rupture valve (boom), disassembly

Load check valve – single, disassembly and assembly

Machine view, waste handler

Machine view

Main pressure relief valve, replacing

Main relief valve, adjustment

Main relief valve, disassembly and assembly

Main spool, disassembly and assembly

Main switch, replacing

Maintenance of Stored Machines, according to Inspection Program

Maintenance service, according to display message

Maintenance service, daily

Maintenance service, every 50 hours

Maintenance service, every 100 hours

Maintenance service, every 250 hours

Maintenance service, every 500 hours

Maintenance service, every 1000 hours

Maintenance service, every 2000 hours

Maintenance service, every 4000 hours

Maintenance service, every 6000 hours

Maintenance service, general

Maintenance

Make up valve, disassembly

MATRIS, reading, export reading

Measuring condition

Measuring of swing bearing clearance

Mode (foot) actuator, replacing

NET 8940-00200 Replace tool for the remote control valve joint

NET 8940-00290 Track motor guide pin

Oil cooler, replacing

Oil level gauge, replacing

Oil-bath air cleaner’s reservoir (optional equipment), clean, and oil, change

Oil-bath air cleaner’s reservoir (optional equipment), filter insert, clean

Oil-bath air cleaner’s reservoir (optional equipment), oil, check

Operation numbers for additional work

Port relief valve pressure, measuring and adjusting

Port relief valve, disassembly and assembly

Preheating coil, replacing

Pre-heating relay, replacing

Proportional solenoid valve (power shift), replacing

Proportional solenoid valve, measuring and adjustment

Pump coupling, installing

Pump coupling, removing

Pump gearbox coupling assembly, replacing

Pump, assembly

Pump, disassembly

Pump, installation

Pump, tools

Quickfit, installing

Quickfit, removing

Radiator hose upper, replacing

Radiator hoses lower, replacing

Radiator outside hydraulic oil cooler outside, cleaning

Radiator, replacing

Rear window, replacing

Rear-view mirror, replacing

Receiver, replacing incl draining and filling

Remote control valve (Lever), assembly

Remote control valve (Lever), disassembly

Remote control valve (Lever), maintenance standard, Specifications

Remote control valve (pedal), assembly 2

Remote control valve (pedal), disassembly

Remote control valve (pedal), maintenance standard, Specifications

Rotator valve, adjustment

Seat support, replacing

Seat, replacing

Servo hydraulic pressure, adjustment

Servo pump, parts inspection

Servo pump, replacing

Side window, replacing

Silencer, replacing

Slew gearbox, lubrication

Slew motor, troubleshooting

Solenoid valve, disassembly and assembly

Solenoid valve, inspection

Speaker, replacing

Spring package, assembly

Spring package, disassembly

Sprocket, measurement of wear

Sprocket, replacing one

Starter motor lead to battery, replacing

Starter motor, testing

Starter relay, replacing

Starter switch (engine start switch), replacing

Straight traveling performance

Swing bath grease, check

Swing gearbox oil level, check

Swing gearbox removed, replacing shaft

Swing gearbox removed, seal replacing

Swing gearbox, assembly 2

Swing gearbox, assembly

Swing gearbox, disassembly

Swing gearbox, maintenance standard

Swing gearbox, replacing

Swing motor gearbox, changing oil

Swing motor relief valve, replacing

Swing motor removed, seal replacing

Swing motor, assembly

Swing motor, disassembly

Swing motor, maintenance standard

Swing motor, replacing brake piston seal

Swing motor, replacing plate (brake)

Swing motor, replacing

Swing ring gear bearing, lubricate

Swing ring gear grease pipe, replacing

Swing ring gear outer seal, replacing 2

Swing ring gear outer seal, replacing

Swing speed

Swing unit, replacing

Test-run and check

The machine, check for external damages, cracks and wear damages

Thermostat, checking

Tools & equipment

Top roller, assembly

Top roller, disassembly

Top roller, measurement of wear

Top roller, replacing one

Track chain assembly, installing

Track chain assembly, removing

Track chain, measurement of wear

Track chain, wear limit

Track gearbox (removed), replacing floating seal

Track gearbox cover, replacing

Track gearbox oil level, check

Track gearbox, assembly

Track gearbox, disassembly

Track gearbox, maintenance standard

Track guard, replacing one 2

Track guard, replacing one

Track motor gearbox, changing oil

Track motor relief valve, replacing

Track motor, assembly

Track motor, disassembly

Track motor, replacing

Track recoil spring (tensioner) assembly, replacing

Track running speed

Track shoe bolts, check

Track shoe, replacing one

Track tension condition, check

Track unit, replacing

Track, adjusting track sag

Travel Speed

Turbocharger, inspecting

Turbocharger, replacing

Valve clearance, check adjust

Valves, adjusting

VCADS Pro, logged errors, read off

V-ECU MID 187 non-Programd, replacing 2

V-ECU MID 187 non-Programd, replacing

V-ECU MID 187 pre-Programd, replacing 2

V-ECU MID 187 pre-Programd, replacing

Vent actuator, replacing

Warranty inspection 100 hours

Warranty inspection 1000 hours

Washer fluid level, check

Water separator filter element, change

Water separator housing, replacing

W-ECU, MID142, changing non-Programd ECU

W-ECU, MID142, changing pre-Programd ECU

Windscreen flusher pump, replacing

Windscreen wiper controller, replacing

Windscreen wiper switch, replacing 2

Windscreen wiper switch, replacing

Windscreen, replacing

Work lighting head lamp assy, replacing 2

Work lighting head lamp assy, replacing

X1 return filter (optional equipment), change

Safety

- CE-marking, EMC-directive

Checklist after a fire or heat exposure

Decontamination

Environmental handling for the future

Environmentally hazardous fluids

Environmentally safe handling

Fire prevention measures

Health hazards with paint, plastics and rubber

Safety concerns everybody!

Safety rules when servicing

Safety when handling oils and fuel

Safety when handling the machine

Safety when using lifting equipment

Safety when working with air conditioning refrigerant

Safety when working with batteries

Safety when working with hydraulic systems

Starting with booster batteries

Waste handling

Working in environmentally contaminated areas

Service Bulletins

- Air conditioning compressor improvement 2

Air conditioning compressor improvement

Attachment shims for clearance adjustment of pin joint

Auxiliary heater

Battery maintenance guideline for long term stock machines

Biodegradable hydraulic oil

Biodiesel fuel for Volvo CE

Blower motor

Bottom roller improvement

Bucket cylinder protection improvement

Cab door latch 2

Cab door latch

Cab update, C-series 2

Cab update, C-series 3

Cab update, C-series 4

Cab update, C-series 5

Cab update, C-series

Cable harness connector, engine

CD & MP3 player

Charged air cooler pipe mounting bracket bolt loosening

Check method on engine oil consumption

Cigar lighter and ashtray change

Coolant pump improvement

Crankshaft and camshaft gear manufacturing improvements

Cylinder liner, specifications

D4 – D7 Alternator improvement

D6 D7 Exhaust gas leakage into the cooling system

D6E and D7E, high pressure pipe leakage

DEF AdBlue AUS32 sampling, method

Diesel fuels – quality and function

Dipstick level gauge improvement for swing gearbox

ECU, functional check

Electric connector

Electric horn improvement

Electric horn

Electrical distribution box

Engine limp home switch wire harness

Engine oil filter hose improvement

Engine oil leakage

Engine speed control switch improvement

Engine starting in the manual mode

Fuel cap improvement

Fuel Level

Fuel pump (Tier 3) manufacturing process improvement

Fuel sampling, method

Fuel tank crack

Heat-resistant kit for RCV leakage

Hose leakage

Hour counter improvement

Hydraulic hose assembly leakage handling

Hydraulic oil

Hydraulic system flushing method

Hydraulic tank air breather

Idler wheel and bushing improvement

Idler yoke, improvement

I-ECU, clock and rear view camera

Improved Volvo quick-fit block

Improvement of return check valve

Injector wire harness for D4E-D6E-D7E

Injector yoke bolt

Injector yoke retention bolt loose

Instrument ECU change

Instrument ECU Improvement

Internal modem change

Leakage at engine oil pump gasket

Line rupture valve hose, improvement

Lower frame improvement

Machine model

Modification of CareTrack wire harness

Muffler improvement

New engine oil cooler

New engine oil level sensor

New fastener assortment

New oil change interval for Volvo bio hydraulic oil

New product

New software

New turbo charger for D6E-D7E

Oil analyses

Oil sampling, method

Oil sampling, sampling points

Operating hour parameter

Pipe leakage

Plastic shims for Boom Arm pin joints

Poor straight travel operation

Portable refillable O-ring kits

Pressure sensor

Receiver drier improvement

Recoil spring grease valve

Recoil spring package rod

Recommendations for Oil Sampling Intervals

Reporting of product misuse & near-miss report

Reports

Reversible fan, modes and setting

Rotating beacon lamp, tightening torque

Routines for reporting cracks on Boom and Arm

Serial number location on machine components

Sprocket improvement

Swing ring gear seal

Thermostat failure (D4, D5, D6 & D7)

Tool box change

Tool box improvement

Travel gearbox floating seal improvement

Travel motor 2

Travel motor

Turbo outlet gasket change

Turbocharger

Volvo Product incident accident report & Interview Form

Washer check valve

Washer pump improvement 2

Washer pump improvement

Waste handler strobe light

Water separator drain valve

Whistle noise during boom down

X1 stop valve

Specifications

- Adjustable boom and cylinder, specifications

Air conditioning unit, specifications

Alternative fuels

Alternator, specifications

Audio remote controller, specifications 2

Audio remote controller, specifications

Auto Manual pump control switch, specifications

Automatic lubrication system, specifications

Battery, specifications

Boom lifting cylinder, specifications

Boom, specifications

Bucket cylinder, specifications

Cab, weight

Circuit breaker, specification

Control lockout lever switch, specifications

Control pattern selector valve, specifications

Coolant pump, thermostat, specifications

Coolant with freezing and corrosion protection

Cooling system, specifications

Counterweight, specifications]

Counterweight, tightening torques 2

Counterweight, tightening torques

Current pressure, specifications

Diesel coolant heater (5kw), specifications

Dipper arm cylinder, specifications

Dipper arm, specifications

Electric horn, specifications

Electrical system, specifications

Electronic climate control unit ECC, specification

Elevating cylinder, specifications

Emergency engine speed control switch, specifications

Engine – Pump control, specification

Engine control unit E-ECU, specifications

Engine speed control switch, specifications

Engine, specifications

Engine, weights

Flywheel, weight

Frame and track unit, specifications 2

Frame and track unit, specifications

Fuel feed pump, specifications

Fuel filler pump, specifications

Fuel pressure, specifications

Fuel system, tightening torques

Fuel tank, specifications

Fuse, specifications 2

Fuse, specifications

Hammer return filter, specifications

Hour counter, specifications

Hydraulic oil cooling system, specifications

Hydraulic pump, specifications

Hydraulic tank, specifications

Keypad, specification

Line rupture valve (arm), specifications

Line rupture valve (boom), specifications

Logic valve, specifications

Lower wiper motor, specifications

Lubrication system, specifications

MA9109 Quickfit solenoid valve, specifications

Machine weight, specifications

Main control valve, specifications

Measurement conversion tables

Preheating, specifications

Pressure accumulator, specifications

Proportional solenoid valve, specifications 2

Proportional solenoid valve, specifications

Radio with CD and MP3 player, specifications

Radio with tape or CD player, specifications

Regulator, specifications

Relay, specifications 2

Relay, specifications

Remote control valve (Lever), specifications

Remote control valve (pedal), specifications

Rotating beacon, specifications

Rotator pump, specifications 2

Rotator pump, specifications

Servo pump, specifications

Slew gearbox, specifications

Slew ring gear, specifications

Solenoid valve, specifications 2

Solenoid valve, specifications

Specifications

Standard tightening torques

Start switch, specifications

Starter motor, specifications

Swing motor, specifications

Tightening torque, specifications 2

Tightening torque, specifications

Track gearbox, specifications

Track motor, specifications

Travel alarm, specifications

Upper wiper motor, specifications

Valve system specifications

Vehicle control unit V-ECU, specifications

Windscreen flusher pump, specifications

Wiper controller, specifications

Wireless control unit W-ECU, specification

Work lights and extra lights, specifications

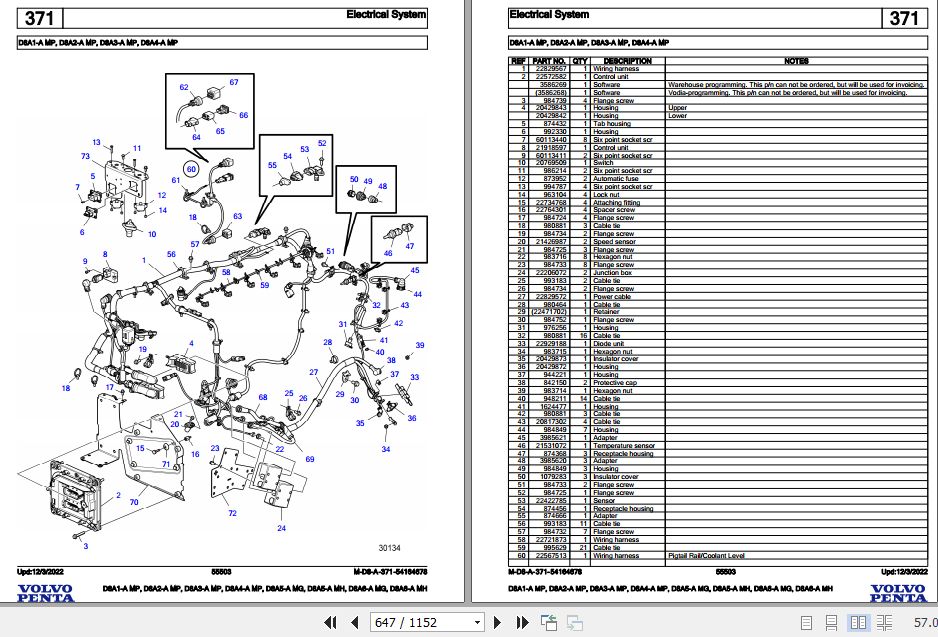

Wiring

- Adjustable boom (X2), hydraulic diagram

Component designations

Component list Control lights warning lights

Component list Alternator, batteries, capacitors, electronic units, voltage outlet

Component list, fuses

Component list, Heating coils

Component list, lights

Component list, Miscellaneous

Component list, motors

Component list, relays

Component list, sensors

Component list, Solenoid valves

Component list, Switches

Control system diagram

Electrical symbols and designations

Explanation of wiring diagrams

Explanations to hydraulic diagram

Grounding points, frame connections

Hydraulic diagram, arm in fig 1

Hydraulic diagram, arm in

Hydraulic diagram, arm out fig 1

Hydraulic diagram, arm out

Hydraulic diagram, boom lower fig 1

Hydraulic diagram, boom lower

Hydraulic diagram, boom raise fig 1

Hydraulic diagram, boom raise

Hydraulic diagram, bucket curl

Hydraulic diagram, bucket dump

Hydraulic diagram, control pattern selector valve

Hydraulic diagram, elevating cab 1

Hydraulic diagram, elevating cab

Hydraulic diagram, ports

Hydraulic diagram, slew (left)

Hydraulic diagram, standard Image 1

Hydraulic diagram, standard

Hydraulic diagram, straight travel

Hydraulic diagram, travel

Hydraulic diagram, with option components image 1

Hydraulic diagram, with option components

Hydraulic diagram, X1 line

Hydraulic quickfit

Hydraulics diagram

Rotator (X3 Line option), hydraulic circuits

Waste handler, electrical circuit

Waste handler, electrical circuit-2

Waste handler, electrical circuit-3

Wiring diagram SCH01

Wiring diagram SCH02

Wiring diagram SCH03 1

Wiring diagram SCH03

Wiring diagram SCH04

Wiring diagram SCH07

Wiring diagram SCH08

Wiring diagram SCH08-1

Wiring diagram SCH10

Wiring diagram SCH11

Wiring diagram SCH11-1

Wiring diagram SCH12

Wiring diagram SCH12-2

Wiring diagram SCH12-3

Wiring diagram SCH13

Wiring diagram SCH14

Wiring diagram SCH14-2

Wiring diagram SCH15

Wiring diagram SCH15-2

Wiring diagram SCH16

Wiring diagram SCH17

Wiring diagram SCH18

Wiring diagram SCH18-2

Wiring diagram SCH20

Wiring diagram SCH21

Wiring diagram SCH22

Wiring diagram SCH23

Wiring diagram SCH24

Wiring diagram SCH27

Wiring diagram, electrical distribution box

Wiring diagram

Wiring harnesses

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution