- No products in the cart.

Volvo EC160B LC Excavator Service Repair Manual PDF

Size: 167.69 MB

Language: English

Make: Volvo

Machine: Excavator

Document: Service Repair Manual, Wiring Diagram, Hydraulic Diagram

Model: Volvo EC160B LC

US $50

Brands:

Volvo

Description

Volvo EC160B LC Excavator Service Repair Manual PDF

Size: 167.69 MB

Language: English

Make: Volvo

Machine: Excavator

Document: Service Repair Manual, Wiring Diagram, Hydraulic Diagram

Model: Volvo EC160B LC

Page: 5517 Pages

Detail Contents:

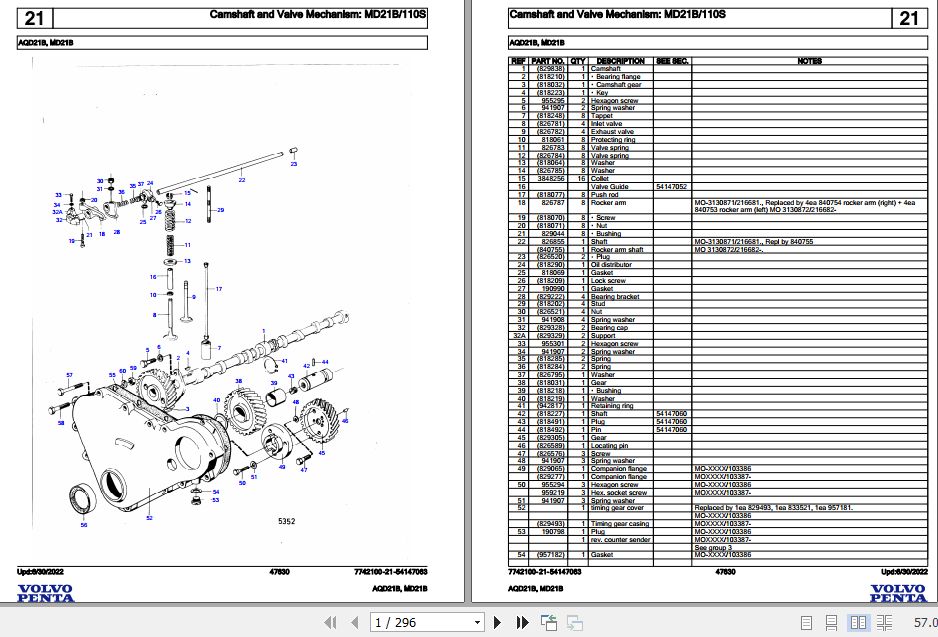

1 Volvo EC160B LC

Description

- 2 stage port relief valve, description

2 stage port relief valve, disassembly and assembly

11 666 140 Multimeter

11 668 006 Extension cable

999 0014 Adapter cable

999 0062 Extension cable

999 3721 Service display unit

999 3893 Adapter cable

999 3894 Template

999 8505 Adapter cable

999 8699 Multi-pin breaker box

8920 – 01805 Wire harness checker

8920 – 01806 Wire harness checker

14515484 Multi-pin breaker box

Actuator, air mix door driver

Actuator, foot face driver

Additional counterweight & digging unit

Adjustable boom (1st boom), description

Adjustable boom cylinder, description

Adjustable boom selector valve

Adjustable boom selector valve1

Adjustable boom valve, description

Air conditioning switch

Air conditioning unit, description

Air inlet vacuum and temperature switch, description

Alarm, description

Alternator, description (new)

Alternator, description

Ambient temperature sensor

Arm holding valve, description

Arm regenerating valve, description

Auto manual select switch, description

Auxiliary start

Basic check, Engine

Battery disconnect switch, description

Battery relay, description

Battery, charging

Battery, description

Battery, storage

Blower motor

Boom float position, description

Boom holding valve, description

Boom lifting cylinder, description

Boom lifting cylinder, troubleshooting

Boom regenerating valve, description

Bottom roller, description

Bucket cylinder, description

Bucket cylinder, troubleshooting

Bucket operation1

Bucket operation2

Center passage, description

Ceramic resistor

Charging, description

Check valve, description

Checking and Adjusting procedure

Collection of basic data

Communication with data buses

Compressor

Condenser

Connecting rod, description

Control lockout lever switch, description

Control pattern selector valve, description

Control pattern selector valve, hydraulic circuits

Control system, description

Control units, software functions

Control units, software functions1

Contronic service display unit, description (I-ECU equipped)

Contronic service display unit, display group 1 general information

Contronic service display unit, display group 1, general information (I-ECU equipped)

Contronic service display unit, display group 2, engine system (I-ECU equipped)

Contronic service display unit, display group 2, engine system

Contronic service display unit, display group 3, electrical system (I-ECU equipped)

Contronic service display unit, display group 3, electrical system

Contronic service display unit, display group 4, hydraulic system (I-ECU equipped)

Contronic service display unit, display group 4, hydraulic system

Contronic service display unit, display group 5, program mode (I-ECU equipped)

Contronic service display unit, display group 5, program mode

Contronic service display unit, display group 6, self diagnosis result (I-ECU equipped)1

Contronic service display unit, display group 6, self diagnosis result (I-ECU equipped)2

Contronic service display unit, display group 6, self diagnosis result

Contronic service display unit, general

Contronic service display unit, texts and translation summary (I-ECU equipped)

Cooling system, description

Cooling system, operation

Crankshaft, description

Cylinder head, description

Cylinder, description

Cylinder, description1

Cylinder, troubleshooting1

Cylinder, troubleshooting2

Data buses, function

DC–DC converter, description

Diesel coolant heater (5kw), description

Diesel coolant heater (5kw), principles

Digging unit, description

Dipper arm cylinder, description

Dipper arm, description

Disassembly and assembly, general

Dozer blade cylinder, description

Dozer blade, description

Dozer blade, hydraulic circuits

Driver’s seat, description

Drying filter

Duct temperature sensor

Electric horn, description

Electrical cables and connectors, checking

Electrical system, description

Electrical system, special instructions for servicing, action when working on machine

Electrical system, special instructions for servicing, electrical components, alternator and charging regulator

Electrical system, special instructions for servicing, electrical components, batteries

Electrical system, special instructions for servicing, electronic components

Electrical system, special instructions for servicing, general

Electronic control system, description

Emergency engine speed control switch, description

Engine block heater, description

Engine characteristic curve

Engine control unit E-ECU, function description

Engine control, operation

Engine oil pressure sensor, description

Engine speed control switch, description

Engine speed sensor (camshaft), description

Engine speed sensor (crankshaft), description

Engine, description (Deutz D6D EBE2)

Error code information, general (I-ECU equipped)

Error code information, general

Error messages on communication and electric system

Error messages on ECUs

Error messages on Engine

Error messages on hydraulic system

Error messages

Evaporator

Examples, hydraulic system

Examples, power transmission

Exhaust system, description

Expansion valve

Foot relief valve (flow sensing valve), description

Fuel Coolant temperature sensor, description

Fuel injection system, description

Fuel level sensor, description

Fuel tank, description

Function of manual air conditioning switch

Hammer and Shears (X1 Line option), description

Hammer return filter, specifications

Heating system, description

Hydraulic components, description

Hydraulic diagram, schematic

Hydraulic pump, description

Hydraulic quickfit, description

Hydraulic tank, description

Idler, description1

Idler, description2

In-car temperature sensor

Inlet system, description

Instrument control unit I-ECU, function description

Instrument panel, description (I-ECU equipped)

Instrument panel, description

Line rupture valve (arm), description

Line rupture valve (boom), description

Line rupture valve (boom), troubleshooting

Link, description

Logic valve, description

Logic valve, description1

Lower line

Lower wiper motor, description

Lubrication system, description

Lubrication system, principle of operation

Machine display unit (MDU), description

Machine display unit (MDU), display status

Machine display unit (MDU), error code displays

Machine display unit (MDU), status indication

Machine display unit, MDU, functional description

Main control valve troubleshooting

Main control valve, description

Main line

Main relief valve, description

Manual air conditioning, description

Multimeter

Overload warning device, operation

Piston cooling

Pistons, description

Port relief valve, description

Power Take Off (PTO, option), description

Preheating, description

Pressure accumulator, description

Pressure relief valve, troubleshooting

Proportional solenoid valve, description

Proportional solenoid valve, troubleshooting

Proportional solenoid valve

Pump control curves

Pump, troubleshooting

Quickfit system, operation

Radio with tape player, description (new type)

Radio with tape player, description

Receiver drier, changing

Recommended lubricants

Refrigerant hoses

Regulator, description

Relay box, description1

Remote control valve (Lever), description

Remote control valve (Lever), troubleshooting

Remote control valve (pedal), description

Remote control valve (pedal), troubleshooting

Resistance box, description

Return and pump line

Rotator (X3 Line option), description

Rotator (X3 Line option), hydraulic circuits and principle of operation

Rotator pump, description

Safety start relay, description

Selection of track shoes

Service connection and programming connection

Service positions

Servo hydraulic line

Servo hydraulic line1

Servo hydraulic selector valve, description

Servo pump, description

Shuttle valve block, description

Shuttle valve for hammer and shear – A type

Single pedal stopper position

Slew gearbox, description1

Slew motor, precautions for operation

Slew motor, tools

Slew motor, troubleshooting

Slow blow fuse, description

Software functions, related to electrical system (I-ECU equipped)

Software functions, related to electrical system

Software functions, related to engine

Software functions, related to hydraulic system (I-ECU equipped)

Software functions, related to hydraulic system

Software parameters, description

Solenoid valve (1) for hammer and shear selection

Solenoid valve (2) for hammer and shear 2-pump flow

Solenoid valve, description

Solenoid valve, troubleshooting

Special tools for troubleshooting

Standard of the setting pressure

Start switch, description

Starter motor, description

Starting engine with booster cables

Starting operation

Stop valve

Swing gearbox, description1

Swing motor, assembly

Swing motor, description

Swing motor, disassembly

Swing motor, maintenance standard

Swing ring gear inner seal, replacing

Three point relay

Tool, multi-pin breaker box

Top roller, description1

Top roller, description2

Track chain, description

Track gearbox, description

Track gearbox, precautions for operation

Track gearbox, principle of operation

Track gearbox, troubleshooting

Track motor, description

Track motor, maintenance standard

Track motor, operating checks

Track motor, precautions for operation

Track motor, troubleshooting

Travel alarm, description

Troubleshooting (5kw)

Troubleshooting strategy

Troubleshooting tools

Troubleshooting, diagnosing procedure

Troubleshooting, general

Troubleshooting

Undercarriage, description

Upper wiper motor, description

Valves, description

VCADS Pro service tool

Vehicle control unit V-ECU, function description (I -ECU equipped)

Vehicle control unit V-ECU, function description

Viscose mount, description

Water temperature sensor

Window limit switch, description

Windscreen wiper, components location

Windscreen wiper, description

Wiper controller, description

Diagrams

- Adjustable boom, hydraulic line

Boom float position, hydraulic circuits

Component designations

Electrical circuit, air conditioner heater

Electrical symbols and designations

Explanations to hydraulic diagram

Ground connections

Hydraulic circuits, arm in boom raise Figure 1

Hydraulic circuits, arm in boom raise

Hydraulic circuits, arm in conflux Figure 1

Hydraulic circuits, arm in conflux

Hydraulic circuits, arm out Figure 1

Hydraulic circuits, arm out

Hydraulic circuits, boom lower Figure 1

Hydraulic circuits, boom lower

Hydraulic circuits, boom raise conflux (internal) Figure 1

Hydraulic circuits, boom raise conflux (internal)

Hydraulic circuits, bucket dump Figure 1

Hydraulic circuits, bucket dump

Hydraulic circuits, neutral

Hydraulic circuits, ports

Hydraulic circuits, slew (right) Figure 1

Hydraulic circuits, slew (right)

Hydraulic circuits, slew priority (slew left arm in) Figure 1

Hydraulic circuits, slew priority (slew left arm in)

Hydraulic circuits, standard Figure 1

Hydraulic circuits, standard

Hydraulic circuits, straight travel (low auto shift) Figure 1

Hydraulic circuits, straight travel (low auto shift)

Hydraulic circuits, straight travel arm (straight travel auto shift, arm in) Figure 1

Hydraulic circuits, straight travel arm (straight travel auto shift, arm in)

Hydraulic circuits, with option components (Machine serial no. ~ 10805) Figure 1

Hydraulic circuits, with option components (Machine serial no. ~ 10805)

Hydraulic circuits, with option components (Machine serial no. 10806 ~ ) Figure 1

Hydraulic circuits, with option components (Machine serial no. 10806 ~ )

Positive feed

Wiring diagram SCH01

Wiring diagram SCH01-1 (I-ECU equipped)

Wiring diagram SCH02

Wiring diagram SCH02-1 (I-ECU equipped)1

Wiring diagram SCH02-1 (I-ECU equipped)2

Wiring diagram SCH03

Wiring diagram SCH03-1 (I-ECU equipped)

Wiring diagram SCH04-1 (I-ECU equipped)1

Wiring diagram SCH04-1 (I-ECU equipped)2

Wiring diagram SCH04-1

Wiring diagram SCH04-2

Wiring diagram SCH05

Wiring diagram SCH05-1 (I-ECU equipped)

Wiring diagram SCH06

Wiring diagram SCH06-1 (I-ECU equipped)

Wiring diagram SCH07

Wiring diagram SCH08

Wiring diagram SCH08-1 (I-ECU equipped)

Wiring diagram SCH09

Wiring diagram SCH09-1 (I-ECU equipped)1

Wiring diagram SCH09-1 (I-ECU equipped)2

Wiring diagram SCH10

Wiring diagram SCH10-1 (I-ECU equipped)1

Wiring diagram SCH10-1 (I-ECU equipped)2

Wiring diagram SCH11

Wiring diagram SCH11-1 (I-ECU equipped)

Wiring diagram SCH12

Wiring diagram SCH12-1 (I-ECU equipped)1

Wiring diagram SCH12-1 (I-ECU equipped)2

Wiring diagram SCH13

Wiring diagram SCH13-1 (I-ECU equipped)1

Wiring diagram SCH13-1 (I-ECU equipped)2

Wiring diagram SCH14

Wiring diagram SCH14-1 (I-ECU equipped)1

Wiring diagram SCH14-1 (I-ECU equipped)2

Wiring diagram SCH15

Wiring diagram SCH15-1 (I-ECU equipped)

Wiring diagram SCH16

Wiring diagram SCH16-1 (I-ECU equipped)

Wiring diagram SCH17

Wiring diagram SCH18

Wiring diagram SCH19

Wiring diagram SCH20

Wiring diagram SCH20-1 (I-ECU equipped)

Wiring diagram SCH21

Wiring diagram SCH21-1 (I-ECU equipped)

Wiring diagram SCH22

Wiring diagram SCH23

Wiring diagram SCH23-1 (I-ECU equipped)

Wiring diagram, Components list and index (I-ECU application)

Wiring diagram, Components list and index

Wiring diagrams

Installation Instruction

- 2.3M arm piping with X1

2.6M arm pip W GR manuovre leakfree

2.6m arm piping wiht X3

2.6M arm piping with Q-Fit

2.6M arm piping with X1

2-switch control on X1(on off,2-way)

3.0m arm piping with Q-fit

3.0M arm piping with X1

3.0M arm piping with X3

5.2m Boom piping wiht X3

5.2m boom piping with Q-fit

5.2M boom piping with X1

Anti vandal kit

Arm cyl.hose rupture on 5.2M boom

Block heater, 120V

Block heater, 240V

Boom float position

Brkt for X3 Q Fit H Rupt

CareTrack

Diesel coolant heater

Extra pip for Slope Rot on X1

Extra work lamp

Fabirc seat with heating & suspension

FOG (Falling Object Guard), installing new

FOG

FOPS (Falling Object Protecting Structure), installing new

FOPS1

FOPS2

Front rain shield

Front rain shield1

Fuel filler pump – 50Lpm+auto stop

Lower wiper

Net kit – front safety window

Net kit – front safety window1

Oil leak line on 5.2M boom

Oil leak line on base machine

Pedal control on X1(prop 2-way)

Pilot control change

Q-fit piping on base machine

Quick fit S1

Quick fit S6

Radio, installing new

Rotating beacon, installing new

Rotation beacon

Rotation beacon1

Safety net, installing new

Sun shield front, roof, rear

Sunlight protection-roof

Travel alarm, installing new

Travel alarm

With hose rupture protection + over load

Work light rear, installing new

X1 modification from 1pump to 2pump

X1 with 2 pump flow

X1 with add retrun filter

X3 piping on base machine

Repair

- 2 stage port relief valve, adjustment

Adjustable boom valve, disassembly

Air conditioning unit, maintenance

Air conditioning unit, refrigerant check and recharging

Arm holding valve, disassembly and assembly

Arm parallel conflux check valve, disassembly

Arm parallel conflux valve, disassembly

Arm regenerating and arm conflux check valve, disassembly and assembly

Attachment bracket, removal

Batteries, replacing

Boom back pressure check valve, disassembly and assembly

Boom holding valve, disassembly

Boom lifting cylinder, disassembly and assembly

Boom lifting cylinder, installation

Boom, installation

Boom, removal

Bottom roller, assembly

Bottom roller, disassembly

Bottom roller, installation

Bottom roller, measurement of wear

Bottom roller, removal

Bottom roller, replacing seal

Bucket cylinder, disassembly and assembly

Bucket, adjustment of bucket clearance

Cab, installing

Cab, removing

Center bypass valve, disassembly and assembly

Center passage, disassembly and assembly

Center passage, inspection and troubleshooting

Coasting left and right swing

Connectors

Counterweight, fitting1

Counterweight, fitting2

Counterweight, removing1

Counterweight, removing2

Creeping of hydraulic cylinder

Cylinder, disassembly and assembly

Determining cylinder head gasket

Digging unit, maintenance

Dipper arm cylinder, disassembly and assembly

Dipper arm, installation

Dipper arm, removal

E-ECU, MID 128, changing non-Programd ECU

E-ECU, MID 128, changing pre-Programd ECU

Engine mounting

Engine speed control switch, inspection

E-tools, NET 8940-00310 Replace tool for the swing ring gear

E-tools, NET 8940-00320 Swing motor guide pin and swing ring gear

Fan motor, replacing

Fitting cylinder head

Foot relief valve (flow sensing valve), disassembly

General, precautions

General, tools

Hydraulic pump coupling, description

Idler, assembly

Idler, disassembly

Idler, installation

Idler, measurement of wear

Idler, removal

I-ECU, MID 140, changing non-Programd ECU

I-ECU, MID 140, changing pre-Programd ECU

Line rupture valve (arm), disassembly

Line rupture valve (boom), disassembly

Line rupture valve relief pressure, adjustment1

Load check valve – single, disassembly and assembly

Load check valve, disassembly and assembly1

Load check valve, disassembly and assembly2

Logic valve, disassembly and assembly

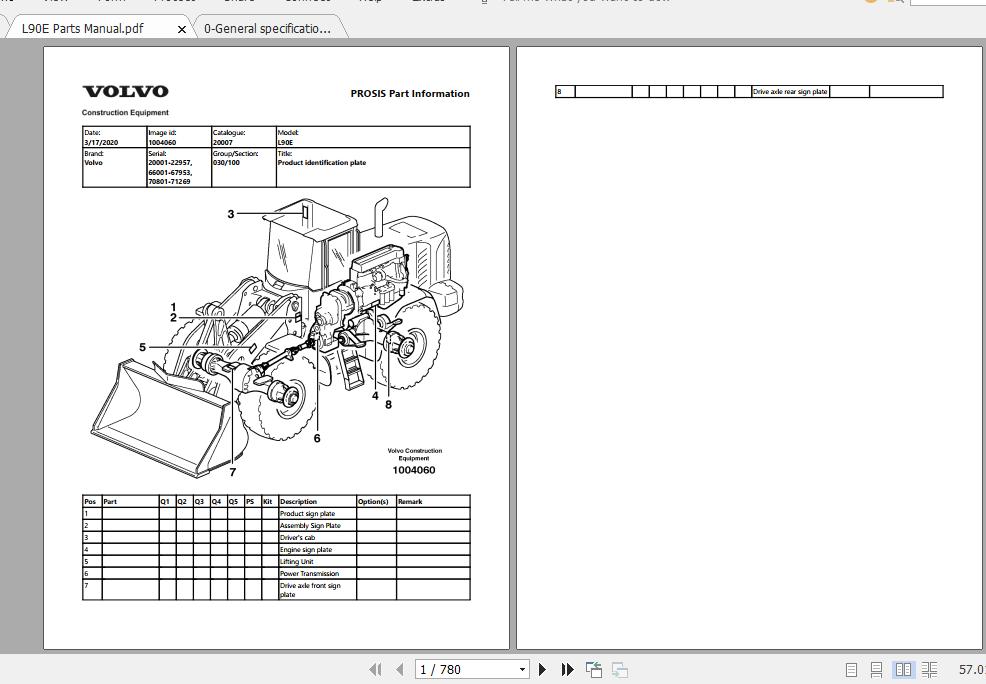

Machine view

Main relief valve, adjustment

Main relief valve, disassembly and assembly

Main spool, disassembly and assembly

Measuring condition

Measuring of swing bearing clearance

NET 8940-00170 Replace tool for the hydraulic tank and fuel tank

NET 8940-00200 Replace tool for the remote control valve joint

NET 8940-00260 Replace tool for the center passage

NET 8940-00290 Track motor guide pin

NET 8940-00400 Replace tool for hydraulic return check valve

Periodic maintenance

Port relief valve pressure, adjustment (when installing or dismantling the line rupture valve)1

Port relief valve pressure, measurement

Port relief valve, adjustment

Port relief valve, disassembly

Proportional solenoid valve, measuring and adjustment

Pump, assembly

Pump, disassembly

Pump, installation

Pump, maintenance standard

Regulator, disassembly

Regulator, maintenance

Remote control valve (Lever), assembly

Remote control valve (Lever), disassembly

Remote control valve (Lever), maintenance standard

Remote control valve (lever), replacing

Remote control valve (pedal), assembly

Remote control valve (pedal), disassembly

Remote control valve (pedal), maintenance standard

Remote control valve (pedal), replacing

Rotator pump, assembly

Rotator pump, disassembly

Rotator pump, parts inspection

Rotator valve, adjustment

Seat, replacing

Servo hydraulic pressure, adjustment

Slew gearbox, assembly

Slew gearbox, disassembly

Slew gearbox, lubrication

Slew gearbox, maintenance standard

Slew gearbox, troubleshooting

Slew ring gear, removal and installation

Solenoid valve, disassembly and assembly

Solenoid valve, inspection

Spring package, assembly

Spring package, disassembly

Sprocket, installation

Sprocket, measurement of wear

Sprocket, removal

Straight travel changeover valve, disassembly and assembly

Straight traveling performance

Superstructure, installing

Superstructure, removing

Swing ring gear inner seal, replacing

Swing speed

Tool attachment, adjustment

Tools & equipment

Top roller, assembly

Top roller, disassembly

Top roller, installation

Top roller, measurement of wear

Top roller, removal

Top roller, tools for disassembly and assembly

Track chain, installation

Track chain, measurement of wear

Track chain, removal

Track gearbox, assembly

Track gearbox, disassembly

Track gearbox, installation

Track gearbox, maintenance standard

Track gearbox, removal

Track link, dimension

Track motor, assembly

Track motor, disassembly

Track running speed

Track, adjusting track sag

Travel Speed

Universal quickfit installation

Valves, adjusting

V-ECU, MID 187, changing non-Programd ECU

V-ECU, MID 187, changing pre-Programd ECU

Viscose mount, installation

Viscose mount, removal

Safety

- Cautions during operation

General precautions

Move and operate machine safely

Preparations for work

Service Bulletins

- A1 solenoid valve coil

Air conditioning compressor improvement

Air conditioning switch

Air conditioning system

Air conditioning unit

Air conditioning unit1

Arm conflux hose improvement

Arm improvement

Attachment pin improvement

Attachment shims for clearance adjustment of pin joint

Auto belt tensioner improvement

Biodegradable hydraulic oil

Boom and dipper arm improvement

Boom pin improvement

B-series Cab improvements

Bumper improvement

Bushing improvement

Cab door handle improvement

Cab door sliding glass replacement procedure

Cab door striker

Cab roof window waterproofing procedure

Cab weather strip replacement

Cable adjustment of Operator’s seat lower slide rail

Cable harness connector, engine

Cable harness for air conditioning system

CareTrack Telematics system

CareTrack, new software version 2008w6

CD & MP3 player

Check method on engine oil consumption

Check method on engine oil consumption1

Circuit changes of the auxiliary diesel heater

Clamping method improvement of the grease pipes on the dipper arms

Coolant level sensor

Coolant level sensor1

Coolant pump improvement

Coolant pump improvement1

Crankshaft and camshaft gear manufacturing improvements

Cylinder liner, specifications

D4 – D7 Alternator improvement

DEF AdBlue AUS32 sampling, method

Diesel fuels – quality and function

Dipstick level gauge improvement for swing gearbox

ECU, functional check

Electric connector

Electric horn

Electrical load capacity

Engine coolant temperature

Engine ECU(E-ECU) Change and Conversion kit

Engine ECU(E-ECU) Change

Engine limp home switch wire harness

Engine oil in the cooling system or coolant in the oil system and external oil or radiator leakage

Engine valve cover gasket improvement

Fan pulley bearing bracket improvement

Fan pulley bearing improvement

Fuel cap improvement

Fuel filler pump service kit

Fuel filter and water separator replacement interval change

Fuel filter change and relocation

Fuel filter modification instruction

Fuel level sender

Fuel Level

Fuel pump improvement

Fuel sampling, method

Fuel tank air breather kit

Fuel tank drain valve

Gas spring

Genuine coolant use

gfsdfgsdfg

Grease nipple commonality

Guidelines of the maximum permissible weight of application tools and load

Handrail improvement

Heat treatment process improvement of the track shoe

Heat-resistant kit for RCV leakage

High altitude Solution

Hose rupture valve improvement

Hydraulic couplings, description

Hydraulic hose assembly leakage handling

Hydraulic pipes improvement

Hydraulic pressure, measuring and adjusting

Hydraulic system flushing method

Hydraulic tank air breather

Hydraulic tank air breather1

Idler improvement

Idler wheel and bushing improvement

Improved dipper arm cylinder lock nut

Improved dipper arm cylinder lock nut1

Improved Fuel Level Sender

Improved heater core

Improved Volvo quick-fit block

Improvement of Main pump hose assembly

Improvement of return check valve

Instrument control unit I-ECU, error symptom

Instrument panel improvement

Instrument panel improvement1

Internal leakage

Leakage at engine oil pump gasket

Line rupture valve hose, improvement

Lubrication point change on swing bearing

Machine model

Main pump shaft seal leakage

MCV arm holding valve block

MCV logic valve stuck

Modification of CareTrack wire harness

New air conditioning control switch

New air conditioning control switch1

New bucket spool in main control valve

New cassette radio

New clamp

New Compact Alternator

New Compact Alternator1

New coolant

New drain pipe in the swing drive unit

New fuel filling hoses

New fuel suction cover

New I-ECU introduction

New I-ECU

New label on the fuel sender

New oil change interval for Volvo bio hydraulic oil

New product

New product1

New Radio Antenna

New slew ring gear seal

New software, I-ECU

New software

New starter motor

New TechTool VCADS Pro interface

New track chain

New track guard

New track guard1

New track master pin

New Track roller_lower

New track roller_upper

New track roller_upper1

Oil analyses

Oil pan leakage protection instruction

Oil sampling, method

Oil sampling, sampling points

Plastic shims for Boom Arm pin joints

Poor grading with RCV

Port relief valve, adjustment

Portable refillable O-ring kits

Pump seal improvement

Quick coupler for pressure test port leakage

QUICK FIT CHANGES

QUICK FIT CYLINDER CHANGES

Quickfit system, operation

Rain visor

Receiver drier pressure switch

Recoil spring improvement

Recoil spring package rod

Recommendations for Oil Sampling Intervals

Repair Instruction for Auto Deceleration Function

Reporting of product misuse & near-miss report

Reports

Revised method for adjusting valve clearance

Right-hand console box

Rotating beacon lamp, tightening torque

Routines for reporting cracks on Boom and Arm

Solenoid valve for rotator

Solenoid valve improvement

Special wire harness for elevated cabin

Sprocket improvement

Strainer improvement

Swing ring gear seal improvement

Swing ring gear seal

The checking method of cooling system

Thermostat failure (D4, D5, D6 & D7)

Tool box change

Tool box improvement

Track drive unit improvement Floating seal leakage

Track link repair kit

Travel gearbox floating seal improvement

Travel motor relief valve O-ring and Back-up ring

Travel motor

Travel motor1

Travel motor2

Turbocharger checking instruction

Turbocharger

V-ECU Hardware

V-ECU Programming

Volvo Product incident accident report & Interview Form

Water separator improvement

Water separator improvement1

Water separator

Windshield wiper wiping range increase

Wire harness protection cover

X1 Line, hydraulic circuits

X1 stop valve

Special Tools, Misc

- Special tool catalog

Special Tools Recommendations

Time Guide Current generation

Time Guide Old generation

Time Guide Previous generation

Specifications

- 2-pump flow selector valve

Adjustable boom cylinder, specifications

Air inlet vacuum and temperature switch, specifications

Alternator, specifications (new)

Alternator, specifications

Auto manual select switch, specifications

Battery disconnect switch, specifications

Battery relay, specifications

Battery, specifications

Boom lifting cylinder, specifications

Boom, specifications

Boost air pressure sensor, specifications

Boost air pressure temperature sensor, specifications

Boost air temperature sensor, specifications

Bucket cylinder, specifications

Charged air cooler, specifications

Control lockout lever switch, specifications

Coolant level sensor, specifications

Cooling system, specifications

Counterweight, specifications

Counterweight, tightening torques

Counterweight, tightening torques1

Current pressure, specifications

DC–DC converter, specifications

Diesel coolant heater (5kw), specifications

Dipper arm cylinder, specifications

Dipper arm, specifications

Dozer blade cylinder, specifications

Electric horn, specifications

Emergency engine speed control switch, specifications

Engine – Pump control, specification

Engine control unit E-ECU, specifications

Engine oil pressure sensor, specifications

Engine speed control switch, specifications

Engine speed sensor (camshaft), specifications

Engine speed sensor (crankshaft), specifications

Engine, specifications

Frame and track unit, specifications

Fuel Coolant temperature sensor, specifications

Fuel level sensor, specifications

Fuel system, specifications

Fuse, specifications1

Fuse, specifications2

Hammer return filter, specifications

Hydraulic pump, specifications

Hydraulic tank, specifications

Instrument control unit I-ECU, specifications

Line rupture valve (arm), specifications

Line rupture valve (boom), specifications

Lower wiper motor, specifications

Lubrication system, specifications

Main control valve, specifications

Measurement conversion tables

Preheating, specifications

Pressure accumulator, specifications

Proportional solenoid valve, specifications

Radio with tape player, specifications (new type)

Radio with tape player, specifications

Recommended hydraulic oil, specifications

Regulator, specifications

Relay box, specifications1

Relay box, specifications2

Relay box, specifications3

Remote control valve (Lever), specifications

Remote control valve (pedal), specifications

Resistance box, specifications

Rotator pump, specifications

Safety start relay, specifications

Servo hydraulic selector valve, specifications

Servo pump, specifications

Slew gearbox, specifications

Slew ring gear, specifications

Slow blow fuse, specifications

Solenoid valve for rotator

Solenoid valve, specifications

Standard tightening torques

Start switch, specifications

Starter motor, specifications

Swing motor, specifications

Track gearbox, specifications

Travel alarm, specifications

Undercarriage, tightening torque

Upper wiper motor, specifications

Vehicle control unit V-ECU, specifications (I-ECU equipped)

Vehicle control unit V-ECU, specifications

Work lights and extra lights, specifications

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution