- No products in the cart.

Volvo BM L90 Wheel Loader Service Repair Manual PDF

Size: 27.19 MB

Language: English

Make: Volvo

Machine: Wheel Loader

Document: Service Repair Manual

Model: Volvo BM L90

US $30

Brands:

Volvo

Description

Volvo BM L90 Wheel Loader Service Repair Manual PDF

Size: 27.19 MB

Language: English

Make: Volvo

Machine: Wheel Loader

Document: Service Repair Manual

Model: Volvo BM L90

Page: 1313 Pages

Detail Contents:

1 VOLVO AND MICHIGAN BM L90

6-wheel drive, basic setting

6-wheel drive, reconditioning

Action to be taken in case of abnormal lubricating oil consumption

Adapters for measuring hydraulic pressure

Air conditioning AC, basic principles

Air conditioning unit, components

Air conditioning unit, operation

Air conditioning

Amendments in Service Manual Engine, D10B; Drive Axle, AWB 40B and Drive Axle, AWB 41

Attachment bracket

Axles, specifications

Bearing cover, reconditioning

Biodegradable hydraulic fluids

Bracket for coolant pump

Brake caliper, reconditioning

Brake piston and wear indicator AHW71L-AHW71N, basic setting

Camshaft 1

Camshaft and tappets, inspection

Camshaft bearing, changing

Camshaft bearings, checking

Camshaft specs

Cdc

Changes in transmission housing HT130 and 131

Charge air cooler, checking for leaks

Checking and adjusting end float, HT 130

Checking pressure, general

Classification of oils

Clutch reconditioning of 1st – 2nd Gear

Clutch reconditioning of 3rd – 4th Gear 1

Clutch reconditioning of 3rd – 4th Gear

Clutch reconditioning of Forward- Reverse 1

Clutch reconditioning of Forward- Reverse

Clutch shaft, sectional view

Compression test, warm engine

Compressor, changing (special instructions)

Compressor, changing magnetic clutch

Compressor, changing pulley bearing (removed)

Compressor, changing shaft seal

Compressor, changing valve plate

Connecting rod, inspection

Connecting rods

Converting R12 to R134a

Coolant pump for charge air cooler, reconditioning

Coolant pump, reconditioning

Copper sleeves for injectors, changing

Crankshaft 2

Crankshaft, checking

Cylinder block specs

Cylinder block, assessing cracks

Cylinder block, checking level

CYLINDER BLOCK, ENGINE TD61

Cylinder block, grinding level

Cylinder head, checking for leaks

Cylinder head, dismantling

Cylinder head, inspection

Cylinder head, milling sealing grooves and flame edge grooves (TD61 and TD71 only)

Cylinder head, surface grinding (TD61 and TD71 only)

Cylinder head, surface grinding (using face plate and abrasive cloth)

Cylinder head

Cylinder liner seat, reconditioning

Cylinder liner, checking and measuring wear

Cylinder liner, fitting

Cylinder liner, removal

Cylinder liners 1

Cylinder liners

Damping valve, reconditioning, HT 130

Delivery pipe

Description cooling

Description cylinder head

Description engine

Description of operation, injection pump

Description, automatic belt tensioner

Description, exhaust brake

Description, feed pump

Description, governor

Description, injection advance mechanism (injection angle advance)

Description, injection pump

Description, overflow valve

Description, pressure valve

Description, pressure-dependent full-load stop (smoke limiter) and cold start device

Description, thermostat

Diesel fuels – quality and function

Diesel test standards

Differential, mounting 1

Differential, mounting

Differential, reconditioning 1

Differential, reconditioning

Drawings of E-tools that can be made in your own workshop

Dropbox HT 130

Dropbox HT 131

E tools, HT 130

Electronic control unit

Engine heather

Engine turbo protection when transporting wheel loaders

Engine, assembly

Engine, dissasembly

Equipment maintenance, changing oil in station

Fan

Final drive AH64J, AH64L, AHW71L, AHW71N, AHW71O, AHW71Q, reconditioning

Final drive AH64K, AHW71M, AHW71P, reconditioning

Final drive, 1st bogie axle, cut-away view

Final drive, front axle and 2nd bogie axle, cut-away view

Final drive, mounting

Fitting of edge saver on buckets

Fluid levels

Flywheel

Foreword Engine

Front three-hole link in loader linkage

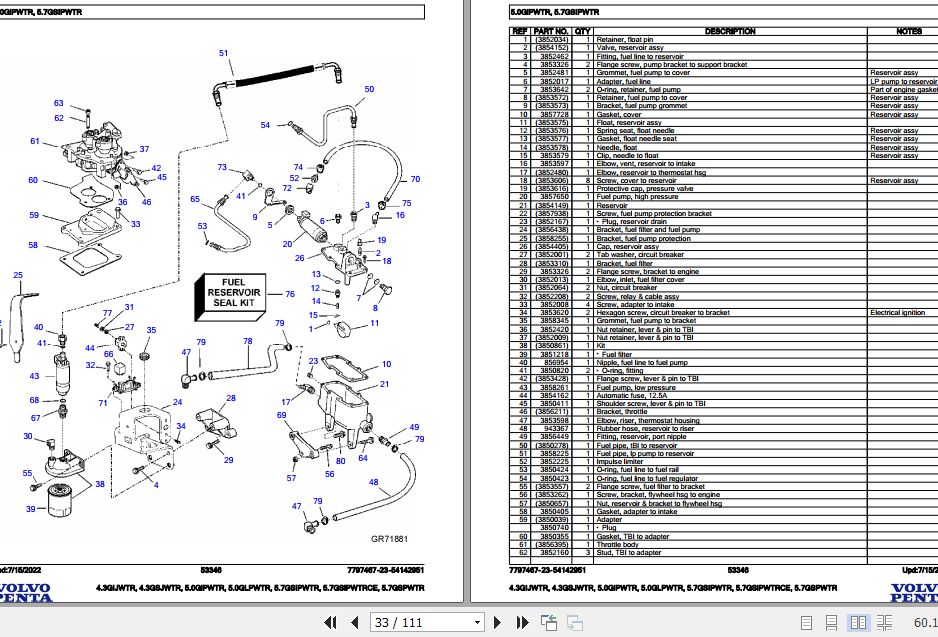

Fuel system sepcs

Gear selector valve, reconditioning, HT 130

General instructions engine

General, HT 130

Heating unit, operation

Hoses and connections

HT 130

Hub end AH64J-AH64L, reconditioning 1

Hub end AH64J-AH64L, reconditioning

Hub end AHW71L-AHW71N, cut-away view

Hub end AHW71L-AHW71N, reconditioning

Hub end AHW71O-AHW71Q, cut-away view

Hub end AHW71O-AHW71Q, reconditioning

Hub reduction AH64J-AH64L, reconditioning

Hub reduction AHW71L-AHW71Q, reconditioning

Inductive sensors

Information about new publications

Information on Bio-diesel fuel (RME-fuel)

Injection angle advance

Injection pump drive, reconditioning

Injection pump, changing

Injection pump, checking and adjusting injection angle (using tool 998 7057)

Injection pump, checking and adjusting injection angle (using tool 999 6848)

Injection pump

Injectors

Instructions for factory reconditioned engines

Intermediate shaft, changing bearings and gears, HT 130

Intermediate shaft, reconditioning

Leak detection

Loud tone horn

Low engine speed (no injection angle advance)

Lubrication system, TD61 and TD63

Lubrication system, TD71 and TD73

Machine data

Main bearings and big-end bearings

Marking pattern, pinion – crown wheel

Modified rear axle suspension

Modified way of attaching radio CR-502

Multi-pin breaker box

New alternator anchorage

New linkage in operator seat

New pressure sensor for brake lights and comfort spring suspension

New propeller shafts

New stop shaft on Bosch injection pump with RQV – governor

New tool for programming the automatic greasing system TWIN

Nitride hardened timing gears

Oil cooler, checking for leaks

Oil dipstick, HT131

Oil pump, reconditioning (double pump)

Oil pump, reconditioning (single pump)

Oil pump, reconditioning, HT 130

Oil pump

Oil sump Specifications

Oil valves, changing

Oils and seals AHW71L-AHW71N

Oils and seals AHW71O-AHW71Q

Oils for Volvo wheel loaders equipped with AWB axles (Axle Wet Brakes)

Oscillation damper

Output shaft 6-wheel drive, reconditioning

Pinion, calculation of axial position

Pinion, mounting

Pinion, reconditioning

Piston and connecting rod, assembly

Piston and connecting rod, dismantling

Piston rings, changing

Piston rings

Pistons

Power divider, assembling

Power divider, mounting

Power divider, reconditioning

Power take off, reconditioning, HT 130

Product plates on HT Transmissions

Production development list for Volvo BM transmissions

Raising and supporting machines (up to and including the E models)

Rear axle suspension

Receiver drier, changing

Reconditioning transmission

Reconditioning, HT 130

Recovering reclaiming refrigerant R134a using recovery unit FRS-10 GS

Recycling refrigerant R134a with station 981 2443

Refrigerant, charging

Refrigerant, discharging

Repair kit, part no

Replacing operator seat shock absorber

Rocker arm mechanism, reconditioning 1

Rocker arm mechanism, reconditioning

Securing pipe in transmission housing, HT 130

Software in E-ECU for engines supplied as spare part

Specifications Engine

Specifications lubrication

Specifications, HT 130

Standard tightening torques

Starter switch

Technical data, station 981 2443

Technical data, station 981 2512

There are three valves in the lubrication system

Thermostat, checking operation

Thermostat

Tightening torques, HT 130

Tools for removing cable terminals

Torque converter, reconditioning (Fichtel & Sachs)

Torque converter, reconditioning (Twin Disc)

Transmission HT131

Transmission, assembling

Transmissions 130

Transmissions 131–132

Transverse differential lock, reconditioning

Transverse differential, adjusting

Troque converter and lubricating oil valve, reconditioning

Turbo Description

Turbocharger, changing

Turbocharger, checking radial and axle clearance

Turbocharger, reconditioning

Vacuum pump 981 2445

Valve guides, changing

Valve seat, changing

Valve seat, machining

Valve stem and valve guide, inspection

Valves and valve seats

Valves

V-belt û replacement

Ventilation servo casing

VOLVO BM standard tightening torques

Volvo standard tightening torques

Water separator improvement

Wear indicator AHW71O-AHW71Q, adjusting

Wear sleeves for front and rear crankshaft seals

Weight (without oil), approx, HT 130

Wheel hub AH64J-AH64L, reconditioning

Wheel hub AHW71L-AHW71N, reconditioning

Wheel hub AHW71O-AHW71Q, reconditioning

Work light

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution