- No products in the cart.

CAT C4.4 MECH Engine Disassembly and Assembly Manual KENR6249 PDF

Size: 30.69 MB

Language: English

Make: Caterpillar

Machine: Engine

Document: Disassembly and Assembly Manual

Model: CAT C4.4 MECH

US $10

Brands:

Caterpillar

Description

CAT C4.4 MECH Engine Disassembly and Assembly Manual KENR6249 PDF

Size: 30.69 MB

Language: English

Make: Caterpillar

Machine: Engine

Document: Disassembly and Assembly Manual

Model: CAT C4.4 MECH

Part Number: KENR6249

Page: 1573 Pages

Detail Contents:

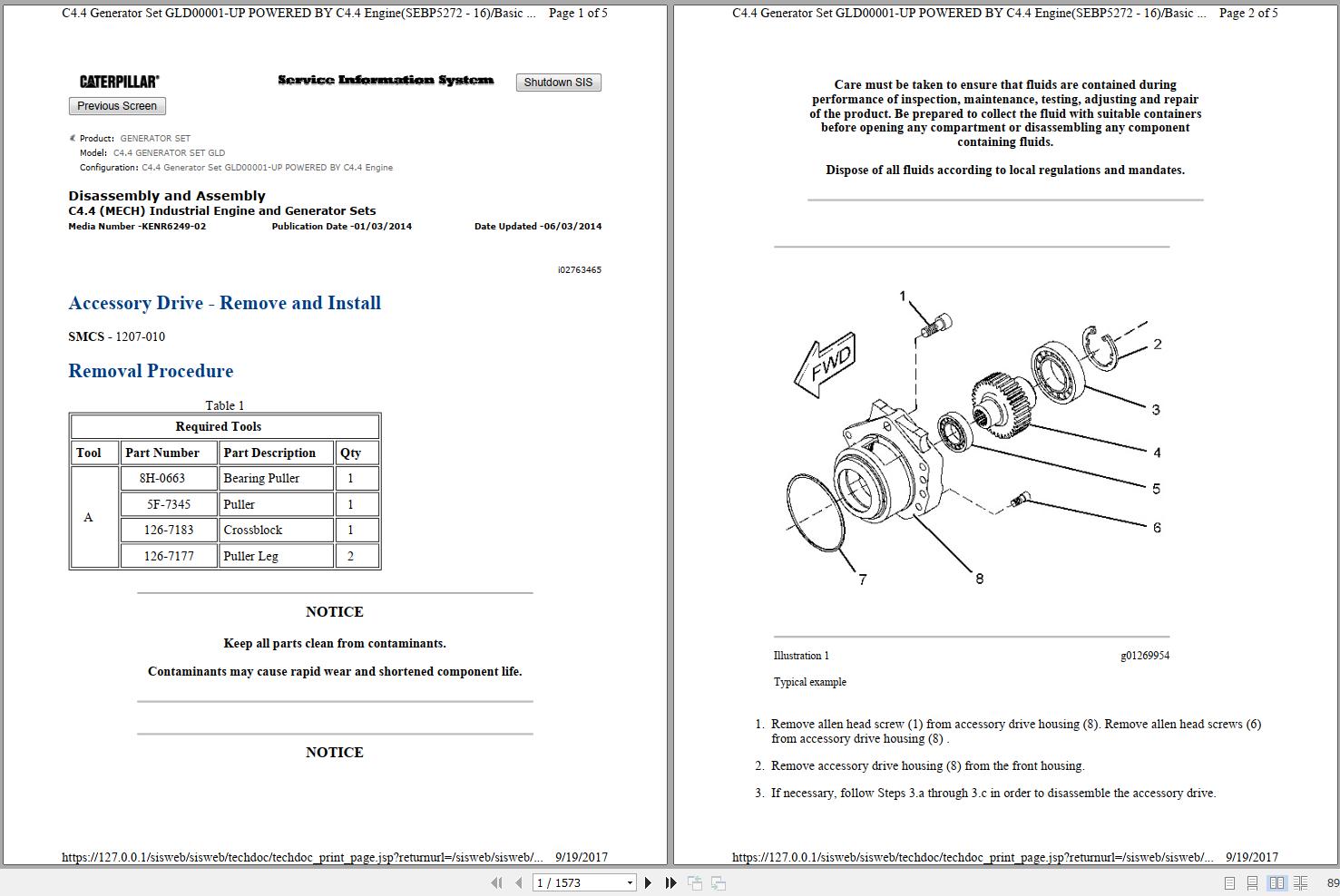

Accessory Drive – Remove and Install

Additional Messages

Air Compressor – Remove and Install

Air in Fuel – Test

Alternator – Inspect

Alternator – Install – Engines With an Automatic Belt Tensioner

Alternator – Install – Engines Without an Automatic Belt Tensioner

Alternator – Remove – Engines With an Automatic Belt Tensioner

Alternator – Remove – Engines Without an Automatic Belt Tensioner

Alternator – Test

Alternator and Fan Belts – Inspect Adjust

Alternator Belt – Remove and Install – Engines With an Automatic Belt Tensioner

Alternator

Analog Input Programming

andunciator Module

Balancer – Install

Balancer – Remove

Battery – Replace

Battery Electrolyte Level – Check

Battery or Battery Cable – Disconnect

Bearing Clearance – Check

Blow-by from Crankcase Breather for C2.2 C3.3 C4.4 and C6.6 Engines(1000 1074 1107 1317)

Boost Pressure Sensor

Burn Prevention

C4-4-Engine

Camshaft – Remove and Install

Camshaft Bearings – Remove and Install

Camshaft Gear – Remove and Install

CAT c4-4-c6-6-Electronic-Application-Installation-Guide

Component Location

Compression – Test

Connecting Rod Bearings – Install – Connecting rods in position

Connecting Rod Bearings – Remove – Connecting rods in position

Control Panel

Cooling System – Test

Cooling System Coolant (ELC) – Change

Cooling System Coolant Extender (ELC) – Add

Cooling System Water Temperature Regulator – Replace

Crankcase Breather – Remove and Install – Naturally Aspirated Engines

Crankcase Breather – Remove and Install – Turbocharged Engines with Filtered Breather

Crankcase Breather – Remove and Install – Turbocharged Engines with Unfiltered Breather

Crankshaft – Install

Crankshaft – Remove

Crankshaft Front Seal – Remove and Install

Crankshaft Gear – Remove and Install

Crankshaft Main Bearings – Remove and Install – Crankshaft in Position

Crankshaft Position Sensor

Crankshaft Pulley – Remove and Install – Engines With an Automatic Belt Tensioner

Crankshaft Pulley – Remove and Install – Engines Without an Automatic Belt Tensioner

Crankshaft Pulley

Crankshaft Rear Seal – Install

Crankshaft Rear Seal – Remove

Crankshaft Wear Sleeve (Front) – Remove and Install

Cycle Timer Programming – EMCP 4.2 Only

Cylinder Head – Install

Cylinder Head – Remove

Data Link

Digital Input Programming

Discrete Input-Output Module

Duo-Cone Seals – Install

ECM Mounting Bracket – Remove and Install

Electric Starting Motor – Remove and Install

Electric Starting System – Test

Electronic Control Module (Engine)

Electronic Control Module (Generator Set)

Electronic Control Module

Electronic Unit Injection (EUI) Engine

Electronic Unit Injector – Install

Electronic Unit Injector – Remove

Engine Air Cleaner Element (Single Element) – Replace

Engine Air Cleaner Service Indicator – Inspect – If Equipped

Engine Design

Engine Identification

Engine Oil and Filter – Change

Engine Oil Cooler – Install

Engine Oil Cooler – Remove

Engine Oil Filter Base – Remove and Install

Engine Oil Pan – Remove and Install – Aluminum and Pressed Steel Oil Pans

Engine Oil Pan – Remove and Install – Cast Iron Oil Pan

Engine Oil Pressure – Test

Engine Oil Pump – Remove and Install – Engines Without a Balancer Unit

Engine Oil Relief Valve – Remove and Install – Engines with a Balancer Unit

Engine Oil Relief Valve – Remove and Install – Engines Without a Balancer Unit

Engine Valve Lash – Inspect Adjust

Event Resetting

Excessive Engine Oil Consumption – Inspect

Exhaust Elbow – Remove and Install

Exhaust Manifold – Remove and Install

Exhaust Temperature – Test

Fan – Remove and Install

Fan Drive – Remove and Install

Finding Top Center Position for No. 1 Piston

Fire Prevention and Explosion Prevention

Fluid Power Graphic Symbols

Flywheel – Inspect

Flywheel – Install

Flywheel – Remove

Flywheel Housing – Inspect

Flywheel Housing – Remove and Install

Foreword

Front Cover – Remove and Install

Fuel Filter 1

Fuel Filter Base – Remove and Install – Secondary Fuel Filter

Fuel Filter Base

Fuel Injection Lines – Install

Fuel Injection Lines – Remove and Install

Fuel Injection Lines – Remove

Fuel Injection Lines

Fuel Injection Nozzle – Test

Fuel Injection Nozzles – Test Exchange

Fuel Injection Pump – Install

Fuel Injection Pump – Remove

Fuel Injection Pump Gear – Install

Fuel Injection Pump Gear – Remove

Fuel Injection Pump

Fuel Injector – Install

Fuel Injector – Remove

Fuel Injector Cover – Remove and Install

Fuel Manifold (Rail) – Remove and Install

Fuel Priming Pump – Remove and Install – Electric Fuel Priming Pump

Fuel Priming Pump and Fuel Filter Base – Remove and Install

Fuel System – Prime

Fuel System Pressure – Test

Fuel System Primary Filter (Water Separator) Element – Replace

Fuel System Primary Filter Water Separator – Drain

Fuel System Secondary Filter – Replace

Fuel Tank Water and Sediment – Drain

Fuel Transfer Pump – Install

Fuel Transfer Pump – Remove

Fuel Transfer Pump

Gear Group (Front) – Remove and Install

General Hazard Information

Generator – Dry

Generator – Inspect

Generator Bearing – Inspect Replace – SR4 Generator

Generator Bearing – Lubricate

Generator Bearing Temperature – Test Record

Generator Lead Connections

Generator Load – Check

Generator Operation

Generator Set Alignment – Check – Generator Sets

Generator Set Communication Wiring Update(1408 1901 7490)

Generator Set Identification

Glow Plugs – Remove and Install

Glow Plugs – Test

High Pressure Fuel Lines

Hoses and Clamps – Inspect-Replace

Housing (Front) – Install

Housing (Front) – Remove

Idler Gear – Install

Idler Gear – Remove

Improved Fuel System Diagnostic Test Documentation for Certain C4.4 and C6.6 Engines(1250 1280)

Inlet and Exhaust Valve Guides – Remove and Install

Inlet and Exhaust Valve Springs – Remove and Install

Inlet and Exhaust Valves – Remove and Install

Inlet Manifold Temperature Sensor

Instrument Panel – Inspect

Insulation – Test

Integrated Voltage Regulator

Kilowatt Relay Programming – EMCP 4.2 only

Lifter Group – Remove and Install

Maintenance Interval Schedule – Prime Power

Maintenance Interval Schedule – Standby

Model View Illustrations

Monitoring Software for Computer

New Priming Pump for Certain C3.3 and C4.4 Generator Sets(1256 1258 1260 1261)

Output Programming

Overhaul Considerations

Piston Cooling Jets – Remove and Install

Piston Ring Groove – Inspect

Pistons and Connecting Rods – Assemble

Pistons and Connecting Rods – Disassemble

Pistons and Connecting Rods – Install

Pistons and Connecting Rods – Remove

Plate Locations and Film Locations

Product Installation

Product Lifting

Product Storage

Real Time Clock Programming – EMCP 4.2 only

Refill Capacities and Recommendations

Resistive Temperature Device Module

Rocker Shaft – Assemble

Rocker Shaft – Disassemble

Rocker Shaft and Pushrod – Install

Rocker Shaft and Pushrod – Remove

Rotating Rectifier – Check

Rotating Rectifier – Test

Safety Messages

Setpoint Programming

Single Unit Operation

Starter Motor

Starting Motor – Inspect

Starting the Engine

Starting with Jump Start Cables

Stopping the Engine

System Pressure Release

Thermocouple Module – EMCP 4.2 only

Troubleshooting

Turbocharger – Inspect

Turbocharger – Install

Turbocharger – Remove

V-Belts – Remove and Install – Engines Without an Automatic Belt Tensioner

Vacuum Pump – Remove and Install

Valve Depth – Inspect

Valve Mechanism Cover – Remove and Install

Voltage Regulators 1

Voltage Regulators

Walk-Around Inspection

Wastegate Solenoid – Remove and Install

Water Pump – Inspect

Water Pump – Install

Water Pump – Remove

Water Temperature Regulator – Remove and Install

Welding on Engines with Electronic Controls

Related Products

US $15

Manual

Manual [HOT] Manual Full Package

[HOT] Manual Full Package Agricultural & Tractor

Agricultural & Tractor Car Automotive

Car Automotive Crane

Crane Forklift Truck

Forklift Truck Heavy Equipment

Heavy Equipment Truck & Bus

Truck & Bus Manual Free

Manual Free Smart Solution

Smart Solution [HOT] Smart Solution

[HOT] Smart Solution Crane Solution

Crane Solution Engineering Computer

Engineering Computer Heavy Equipment Solution

Heavy Equipment Solution